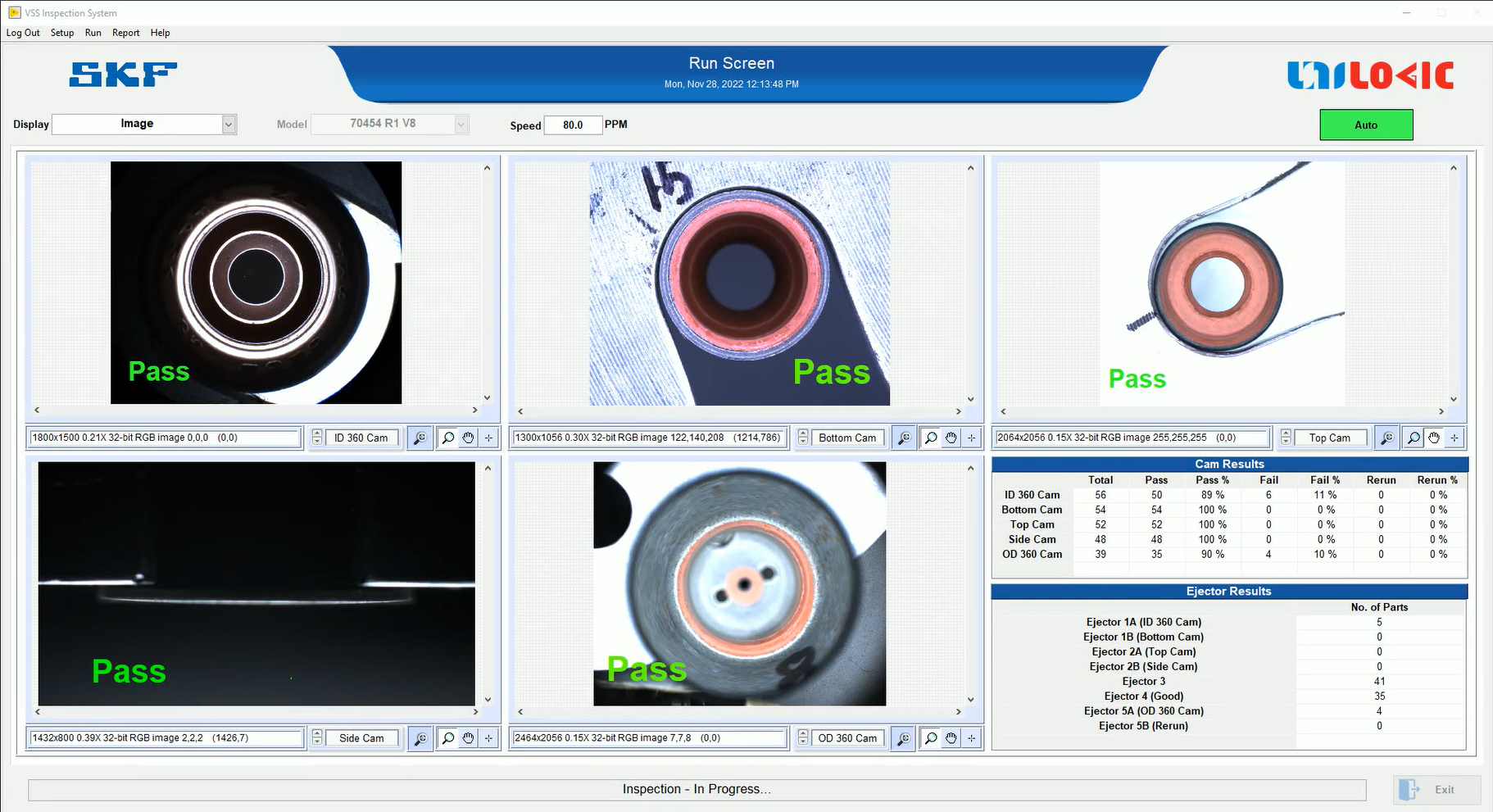

In the field of valve stem seal inspection, manual inspection methods have certain limitations. To address these challenges, an advanced vision system has been developed to provide an efficient and high-speed solution. This system is capable of inspecting valve stem seals at a remarkable speed of 70 – 80 seals per minute, based on their dimensions.

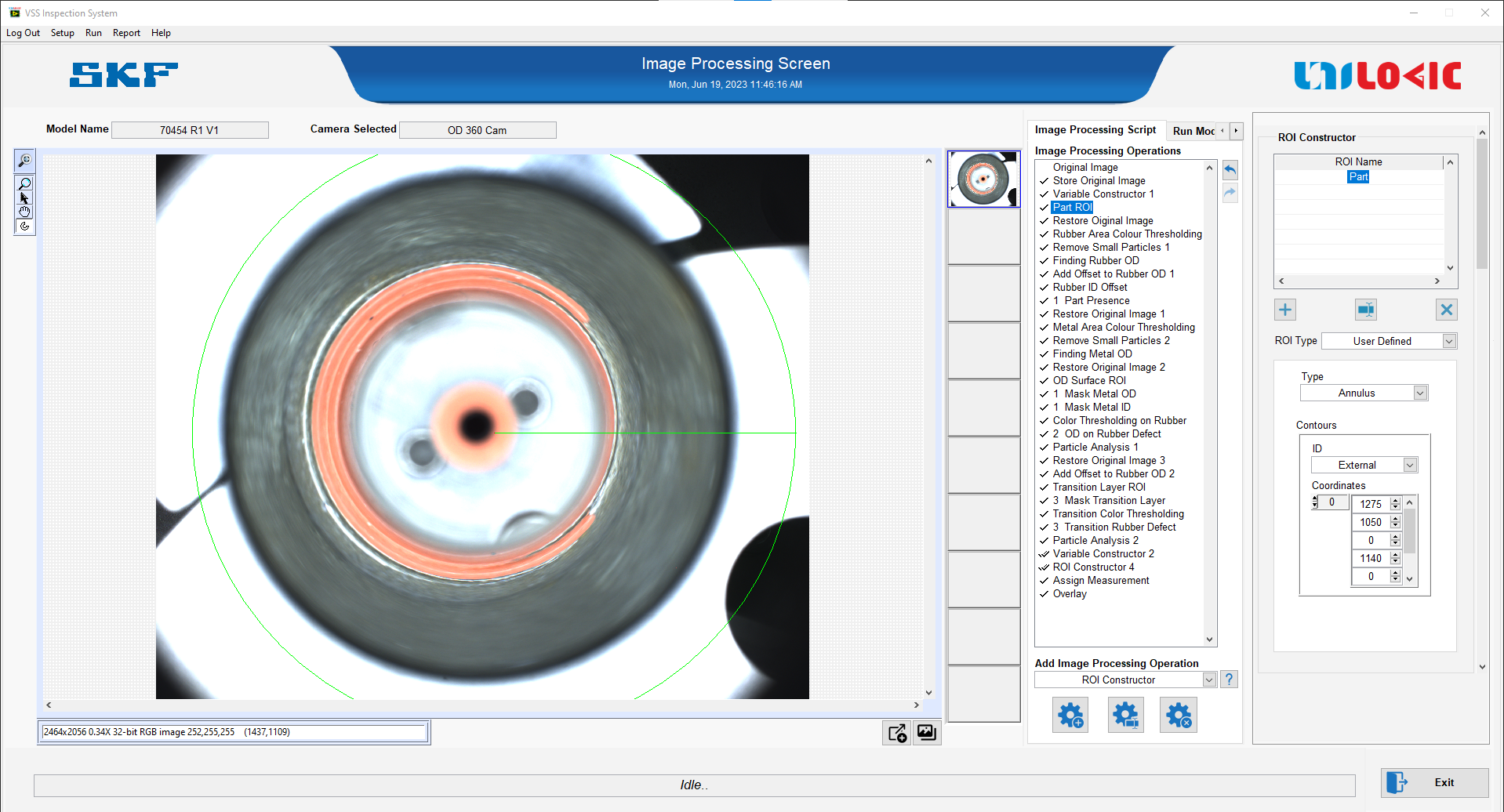

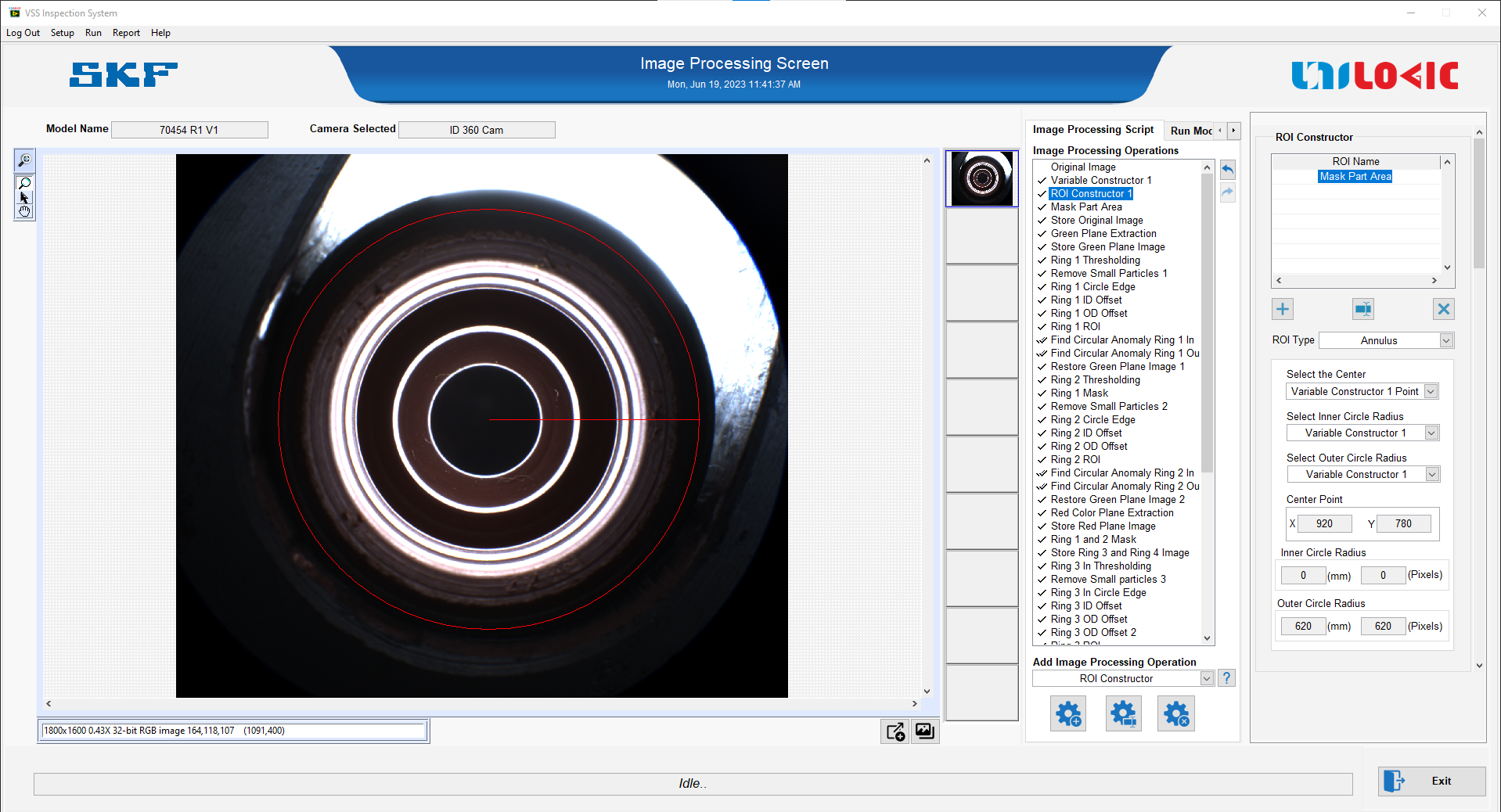

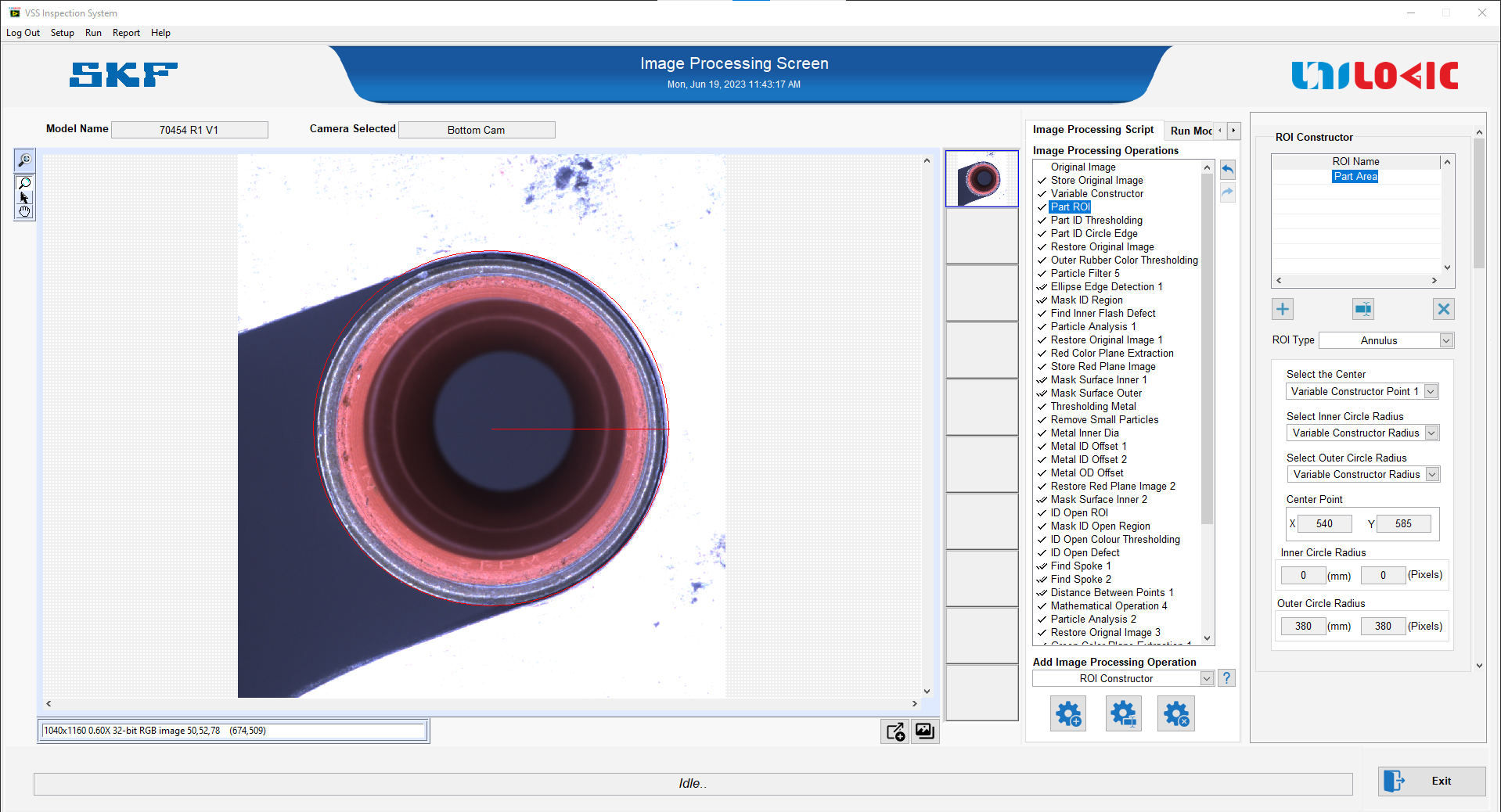

The vision system is fully controlled by a customized machine vision software. It utilizes two circular indexing tables, one with 16 stations and another with 8 stations, strategically designed to minimize machine space while maximizing productivity. These tables facilitate the seamless movement of loaded parts through 15 different stations, ensuring comprehensive inspection and efficient handling.

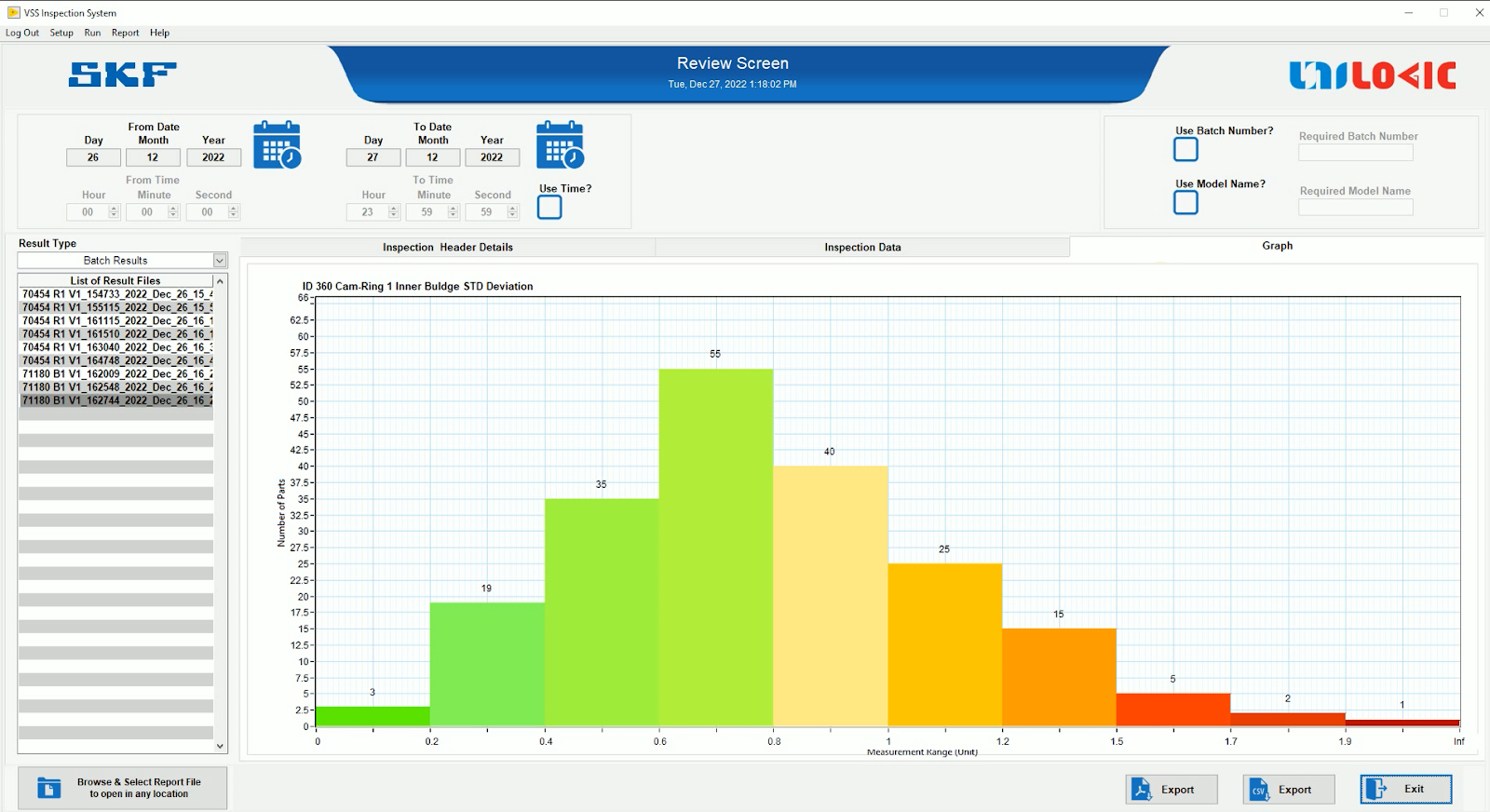

The vision system performs a thorough inspection of the valve stem seals, focusing on the top, outer, and inner surfaces. Each station within the indexing tables is allocated to specific functions, including top view inspection, side view inspection, bottom view inspection, ID 360° surface inspection, OD 360° surface inspection, and shifting the part from the fixture to the good part conveyor. In case any defects are detected, the system promptly ejects the defective products into designated bins based on the type of defect.