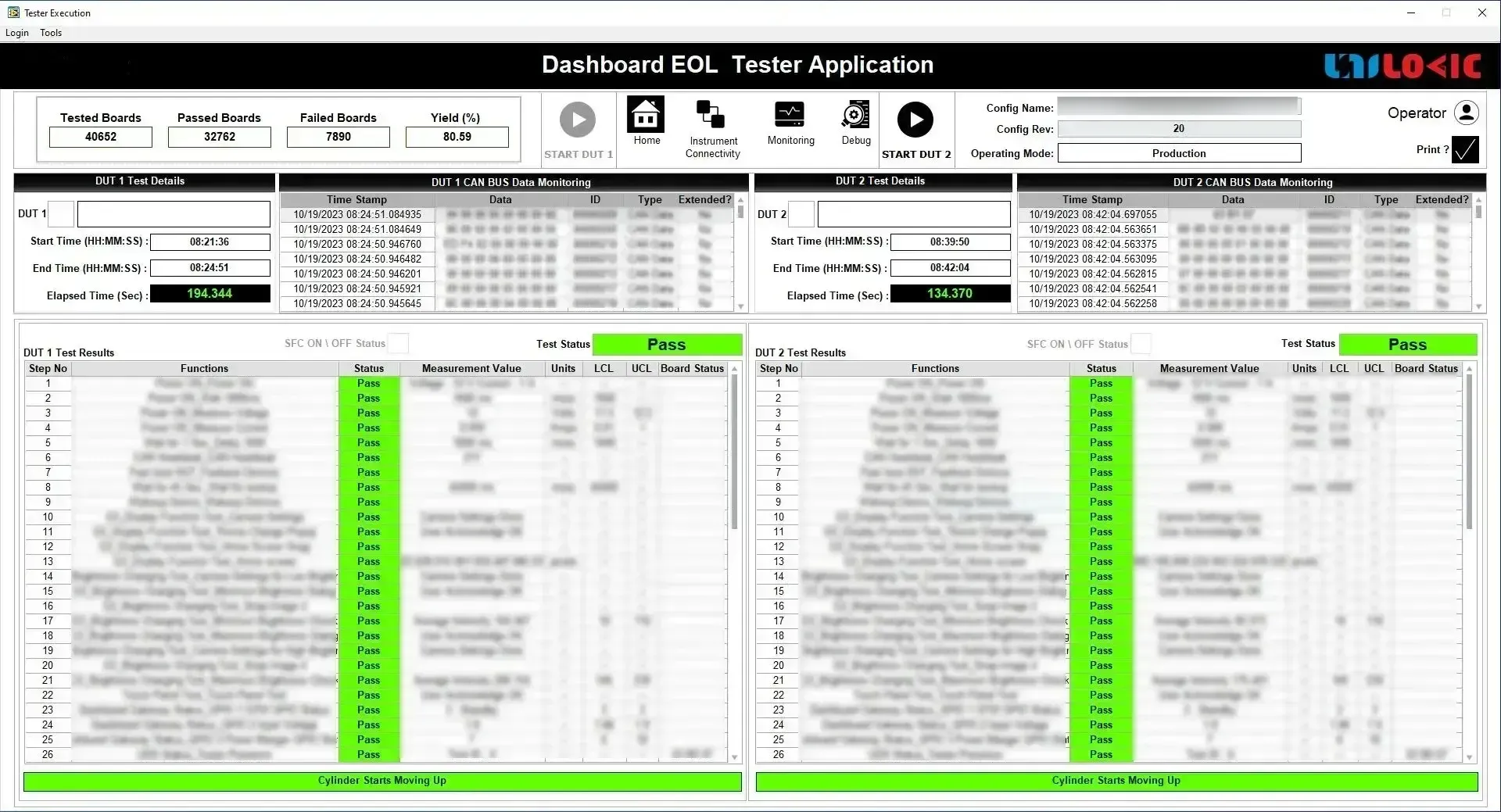

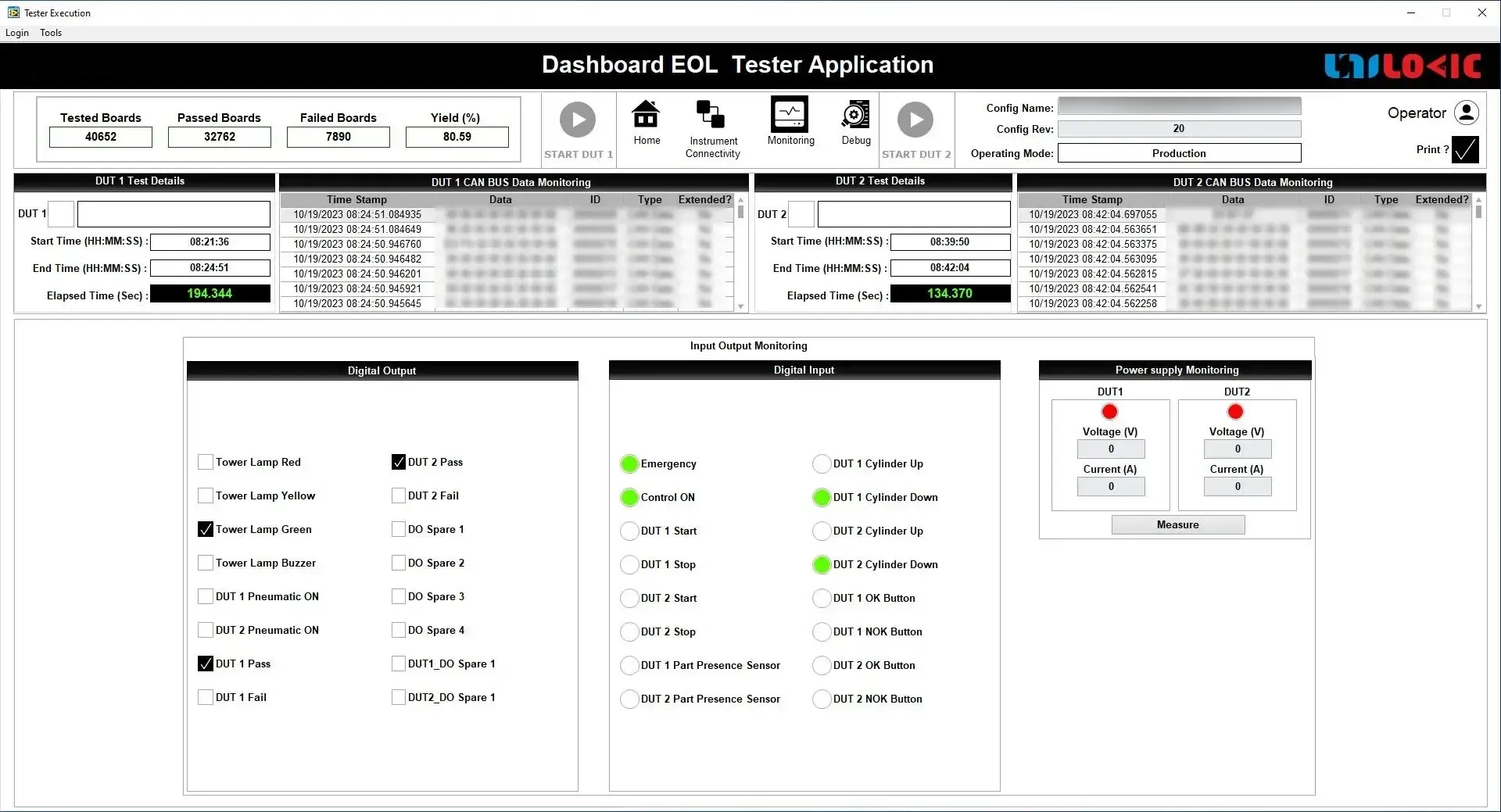

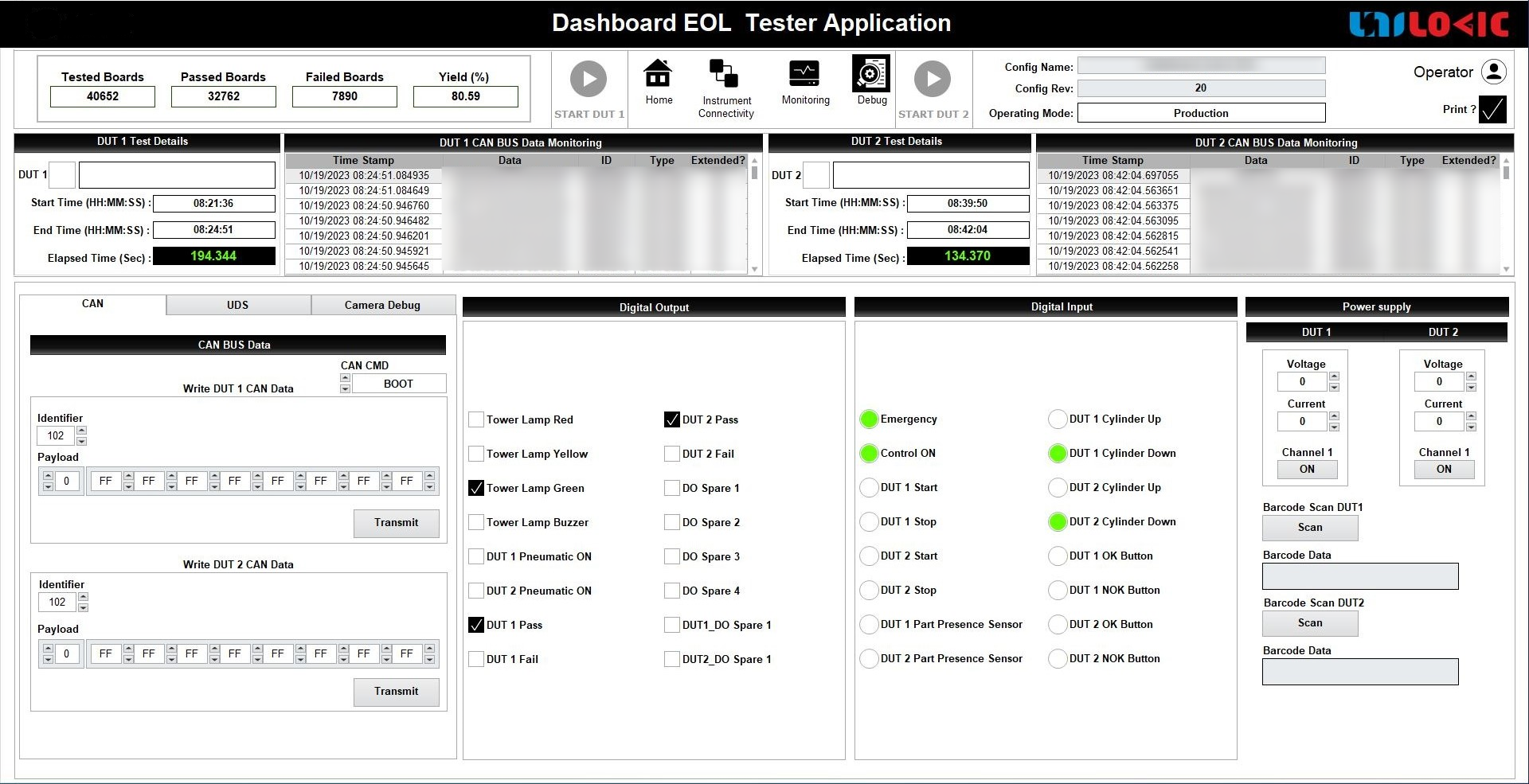

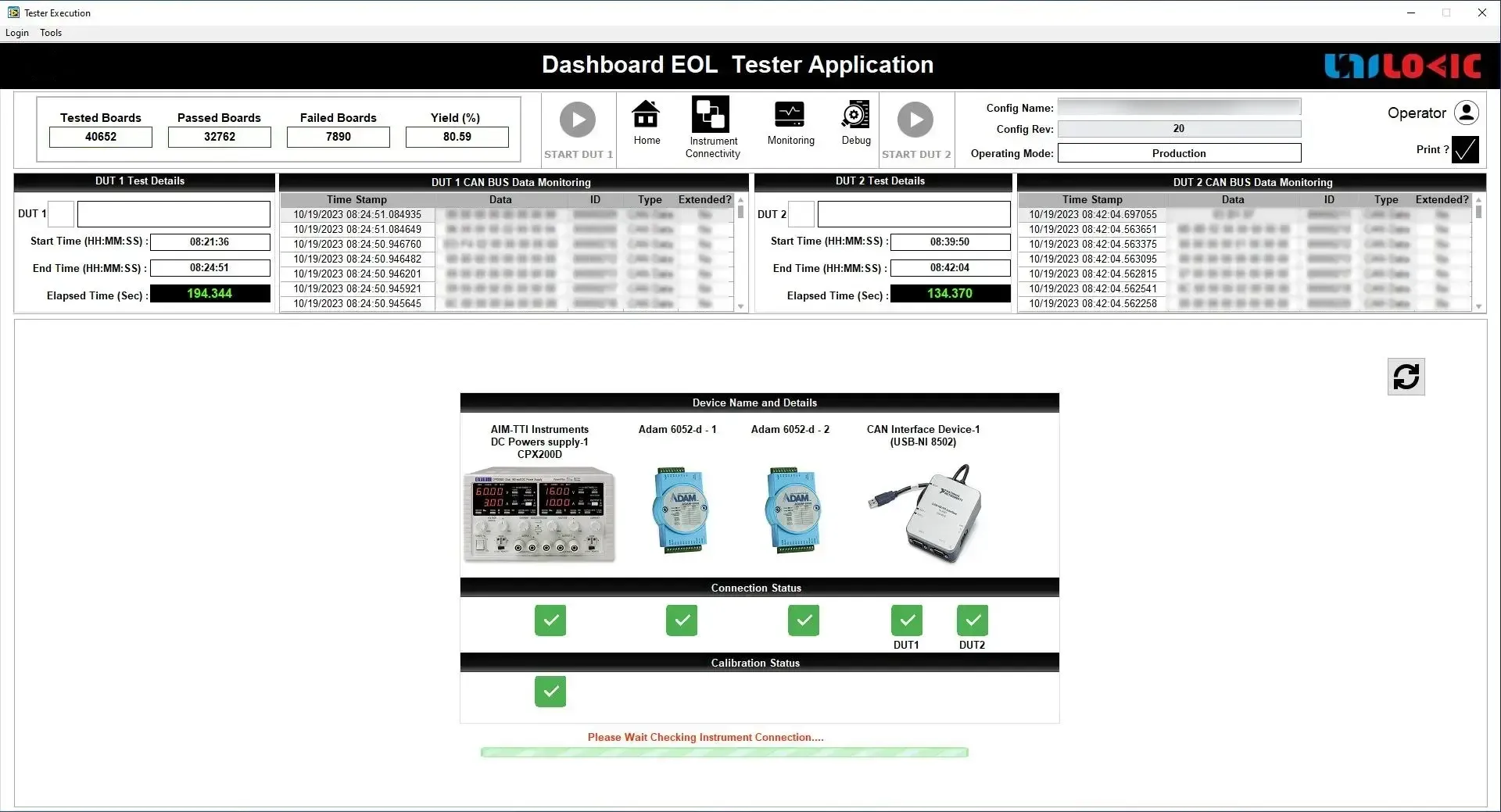

The electric vehicle (EV) Dashboard EOL inspection system is designed to inspect EV dashboards clusters. This system assesses the operational functionality of the EV dashboard by employing cameras for visual inspection. The system adheres to the Unified Diagnostic Services (UDS) and Controller Area Network (CAN) protocol and comprises two stations capable of both parallel and individual inspections. It examines all User interface screens, including the Home screen, Brightness adjustment screen, GPS screen, Setting screen, and more. This system can identify defects such as dark spot, white Spot, pixel damage, and any malfunctions in the display using customized RGB display testing.

The inspection process of each Device Under Test takes approximately 180 seconds. Additionally, the system allows for the inspection of custom screens and records the sequence of operations. All captured images are stored in a designated space, along with a report in MS Excel format.