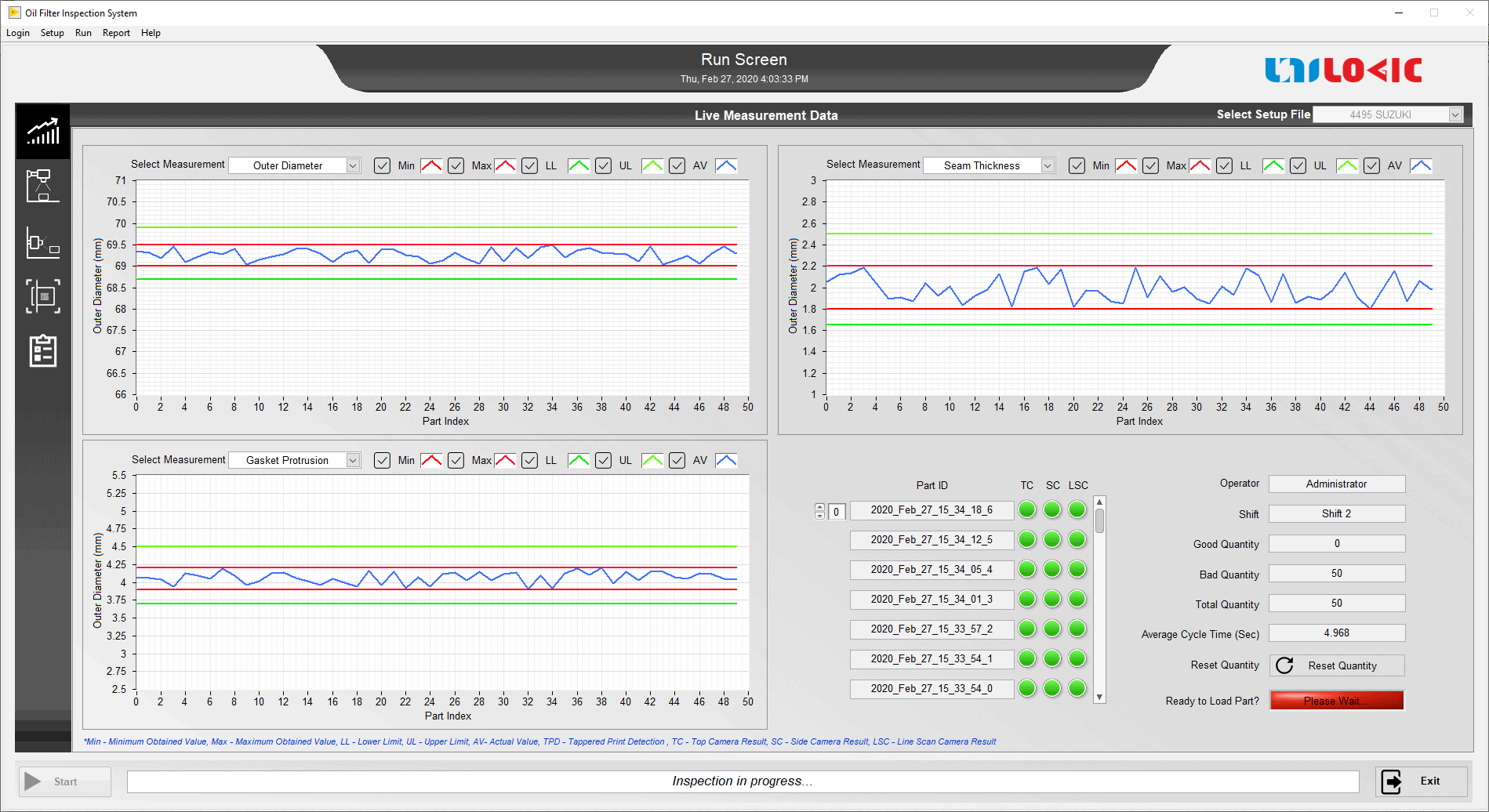

To overcome the limitations in the manual inspection of the oil filter (dimensions and surface defects), we provide a precise and high-speed vision system to inspect the products within 5 seconds.

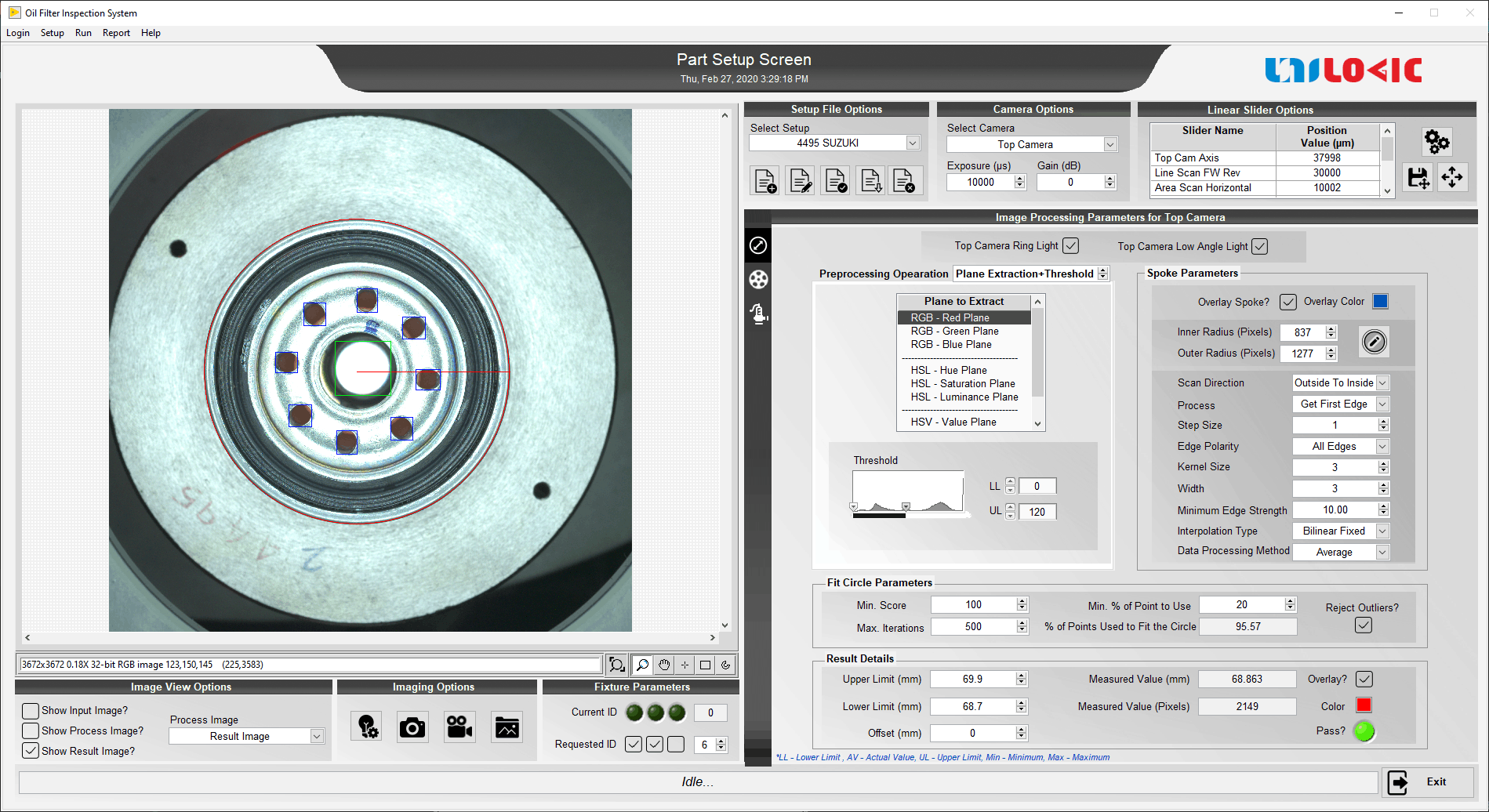

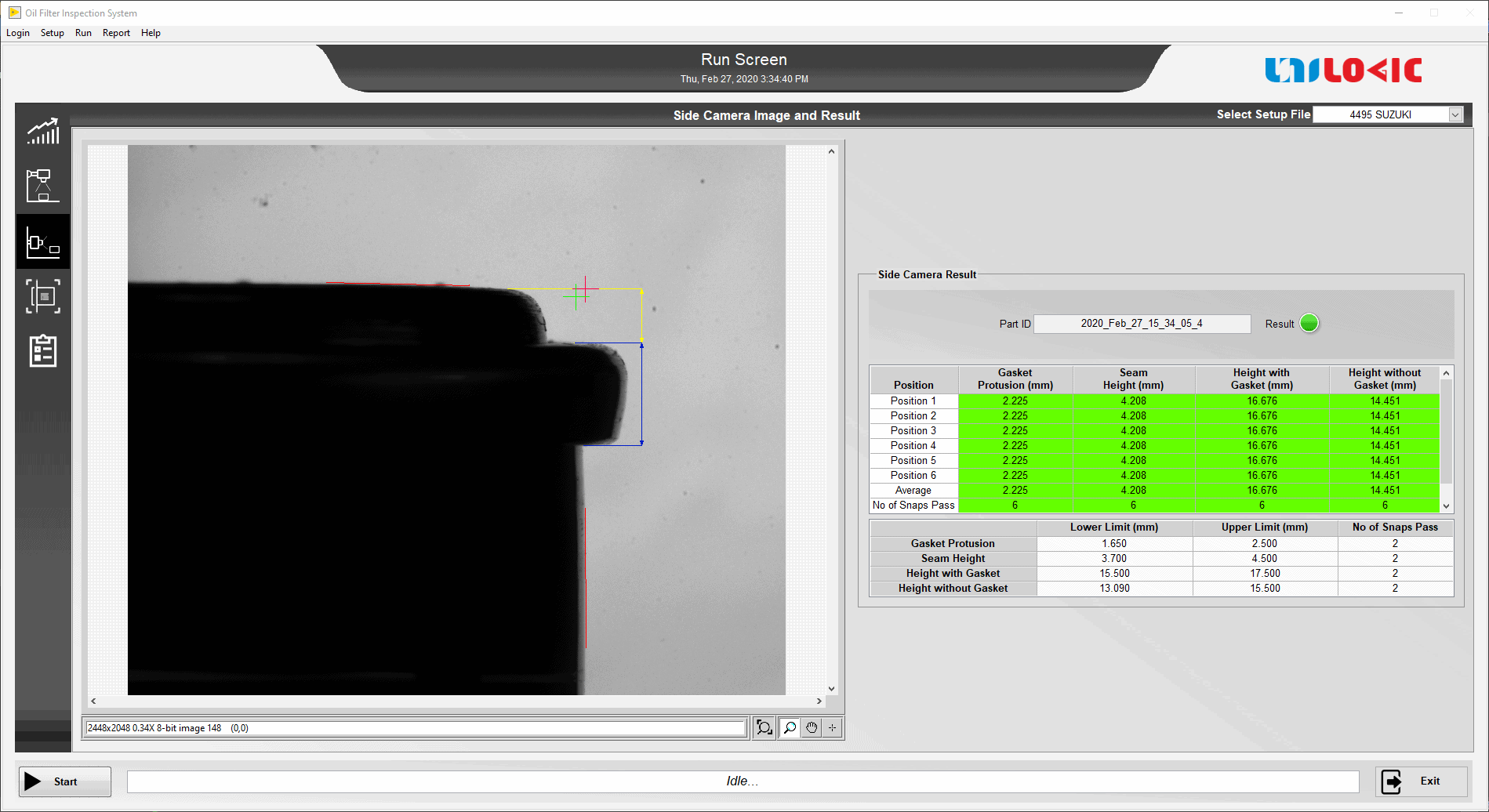

Dimensions such as outer diameter, Seam height, gasket protrusion, filter height with gasket, and height without gasket are measured and verified by the vision system. It also inspects the presence of Check valve & relief valve, inlet holes count, and printing defects along the surface.

The vision system is fully controlled by customized machine vision software. The loaded part will be carried to 6 different stations in a circular indexing table to minimize the machine space. Each station is allocated to specific functions such as top view inspection, side view inspection, printing defect inspection, shifting the part from fixture to good part conveyor, and failed component conveyor.

The system is built up with highly precise motion control products and it supports filters with different dimensions and colour.