Our O-Ring Inspection System automates the inspection process, eliminating manual inspection errors. This system is capable of inspecting seals at a rate of 180 seals per minute.

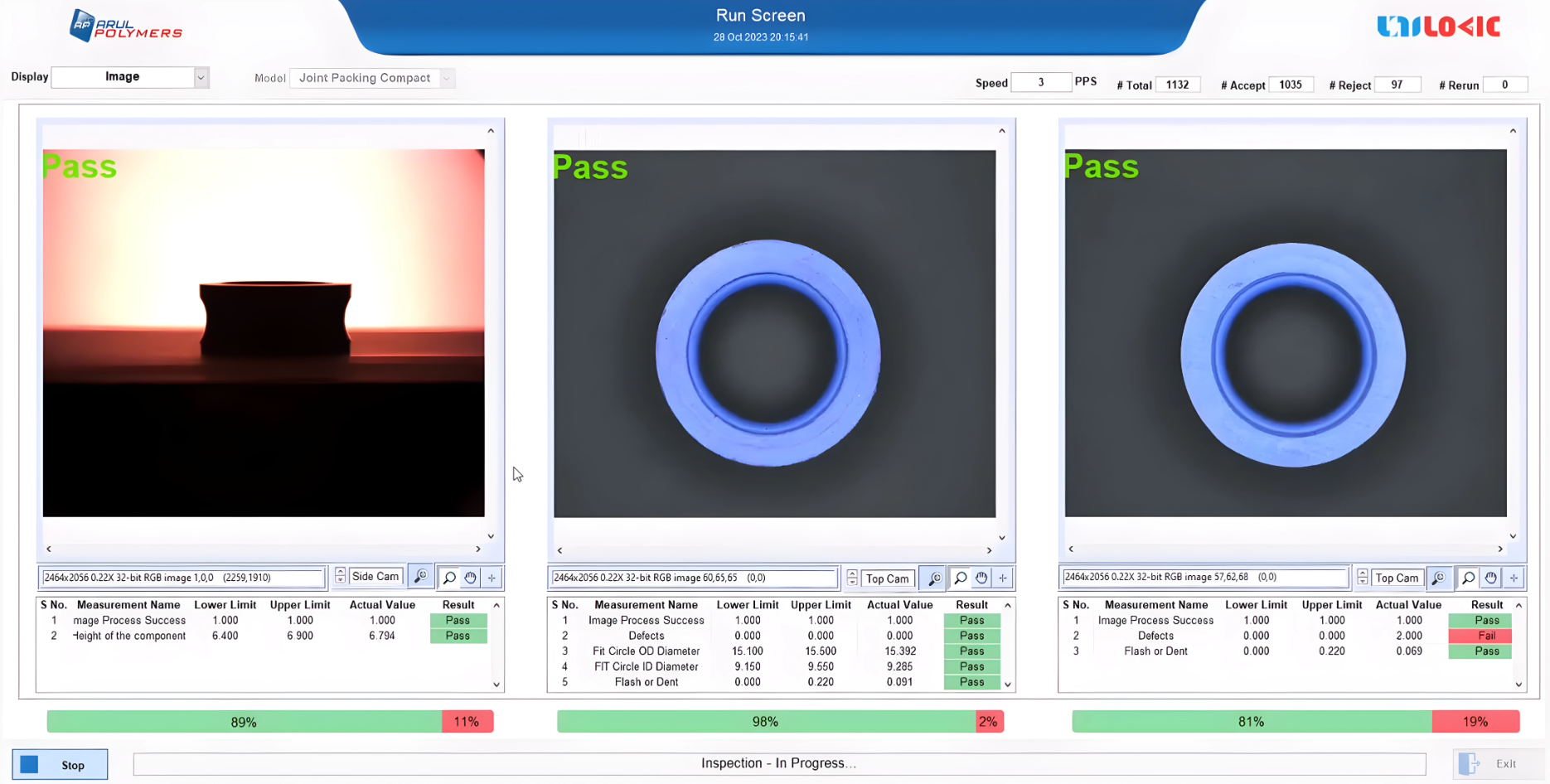

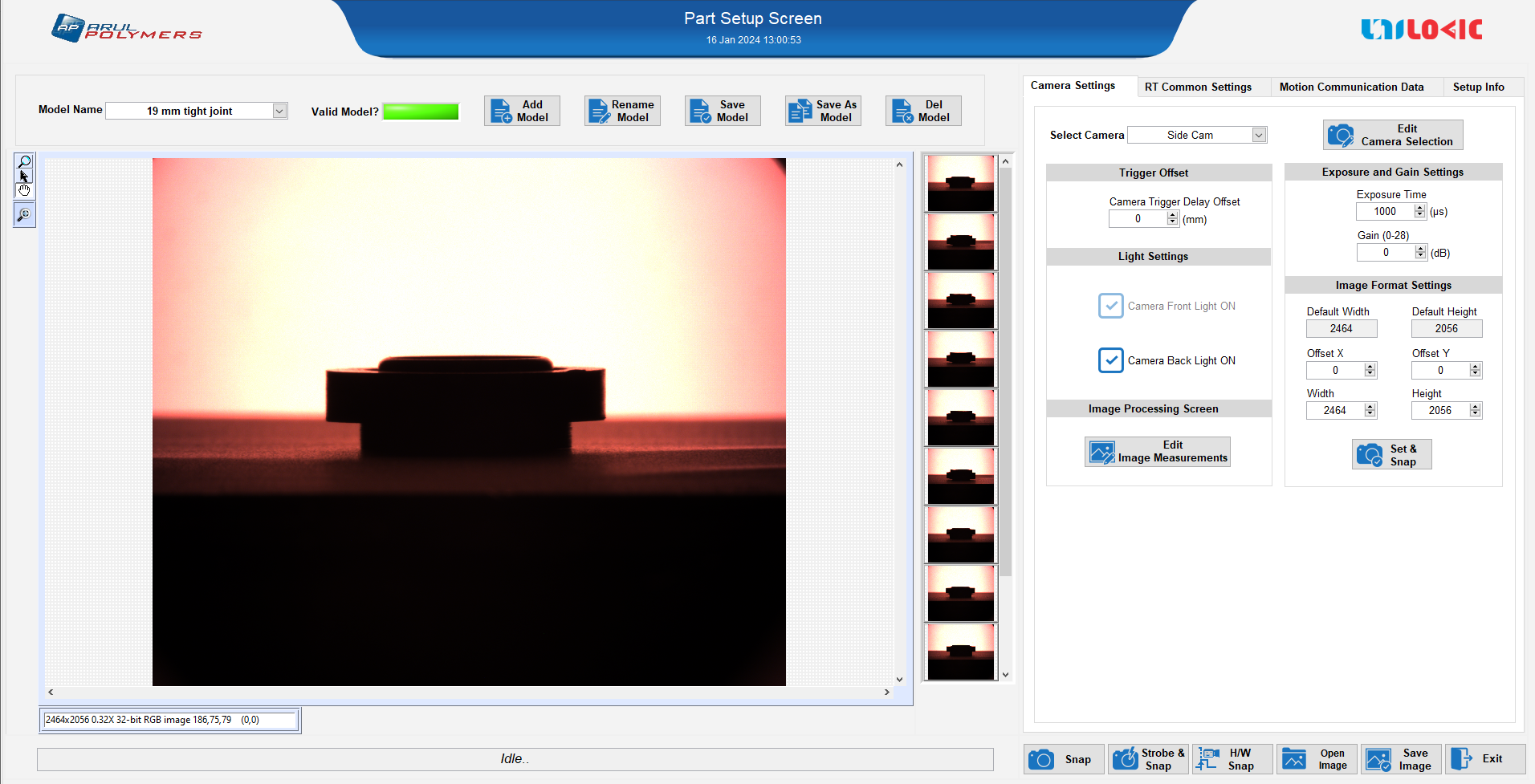

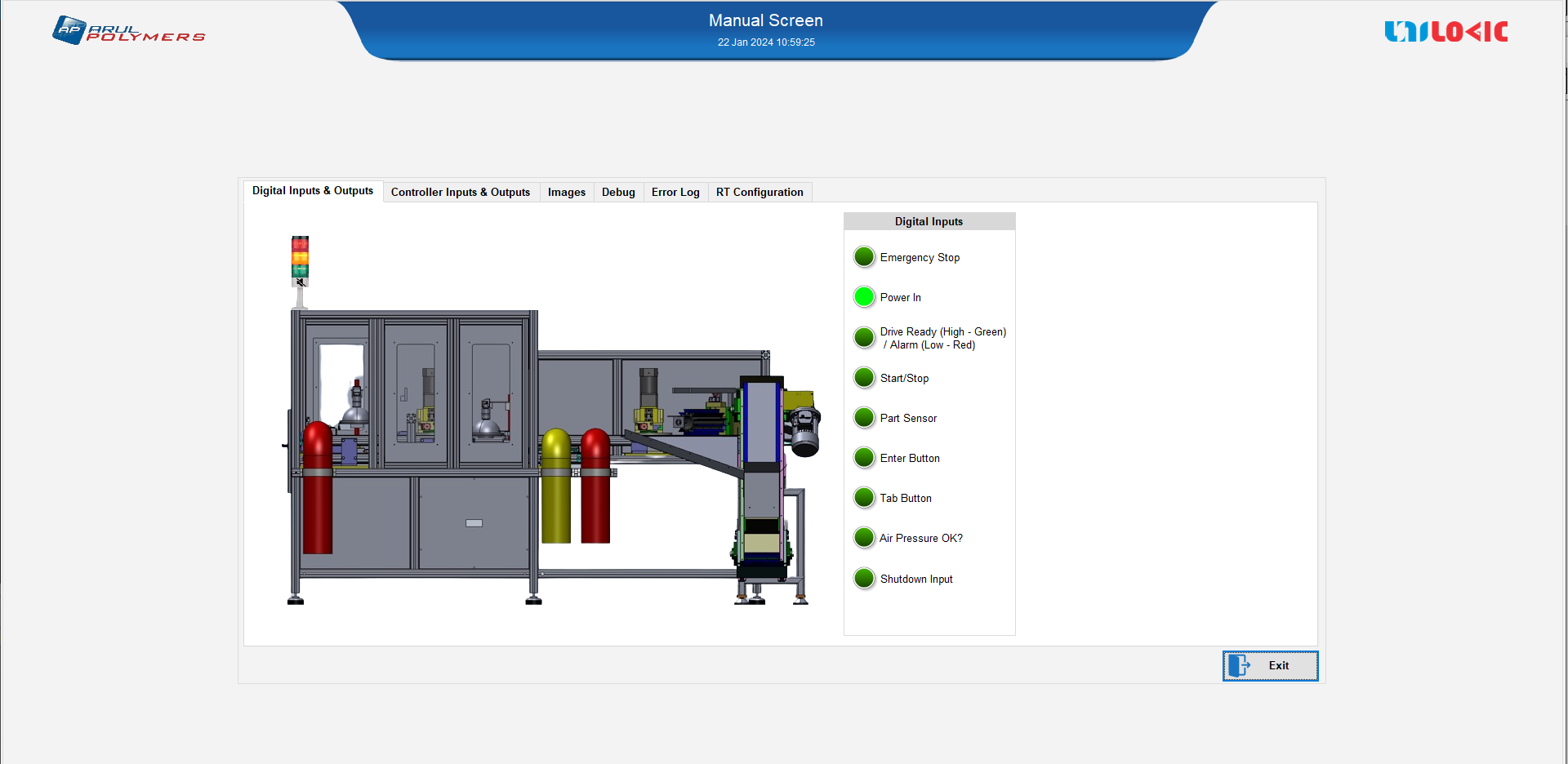

The operator loads the seals onto the bucket conveyor feeding system, which then feeds them to the inspection system in an aligned manner through a conveyor. Images are captured from various angles and positions (Top, Side, and Bottom using a flipping mechanism) for analysis.

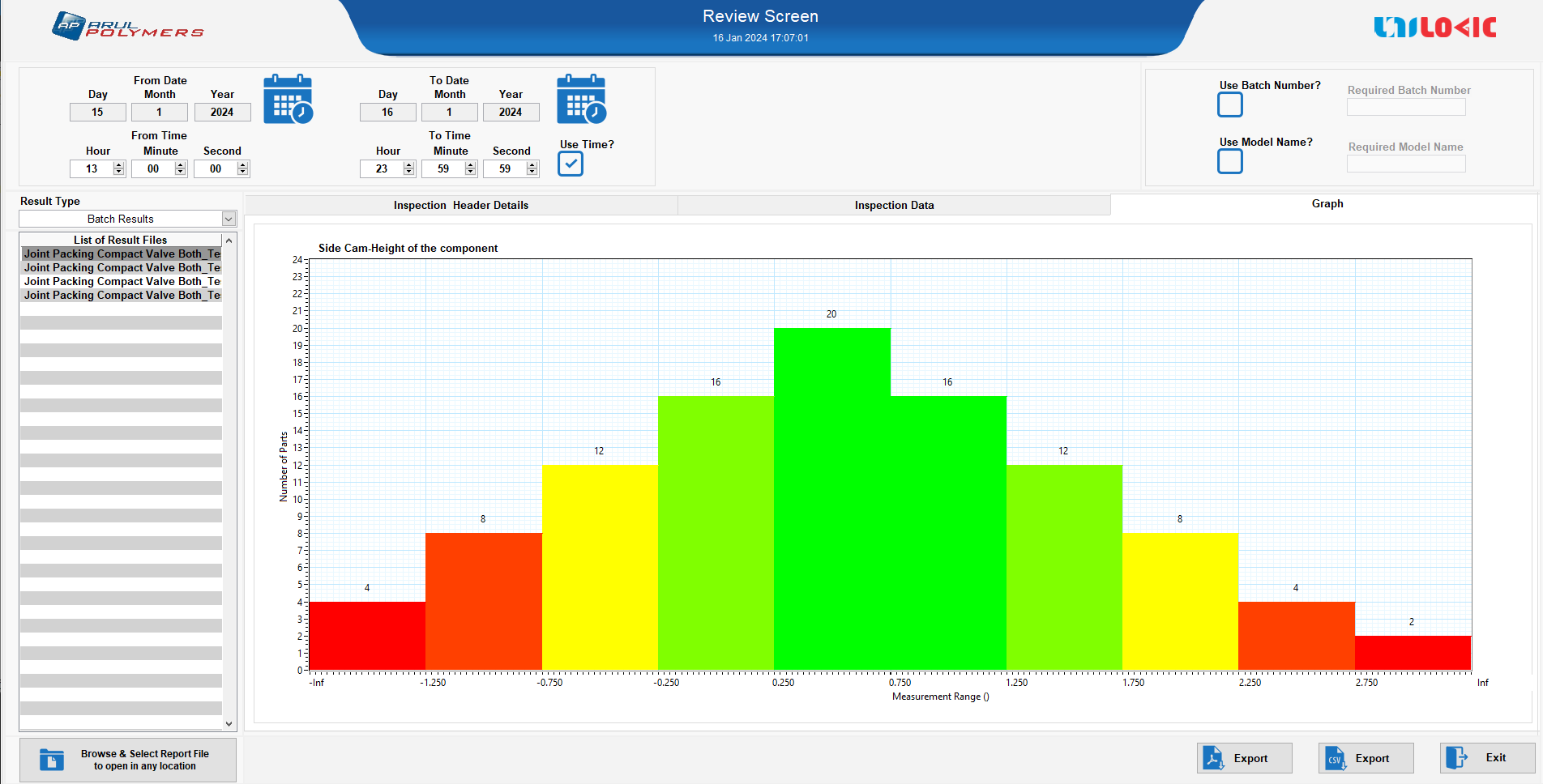

The collected images are processed using custom image processing algorithms. These algorithms enable the software to distinguish between acceptable (OK) and defective (Not OK) parts. Any rejected parts are directed to a designated rejection bin using a pneumatic ejector, while the accepted parts are collected at the end in a good bin.