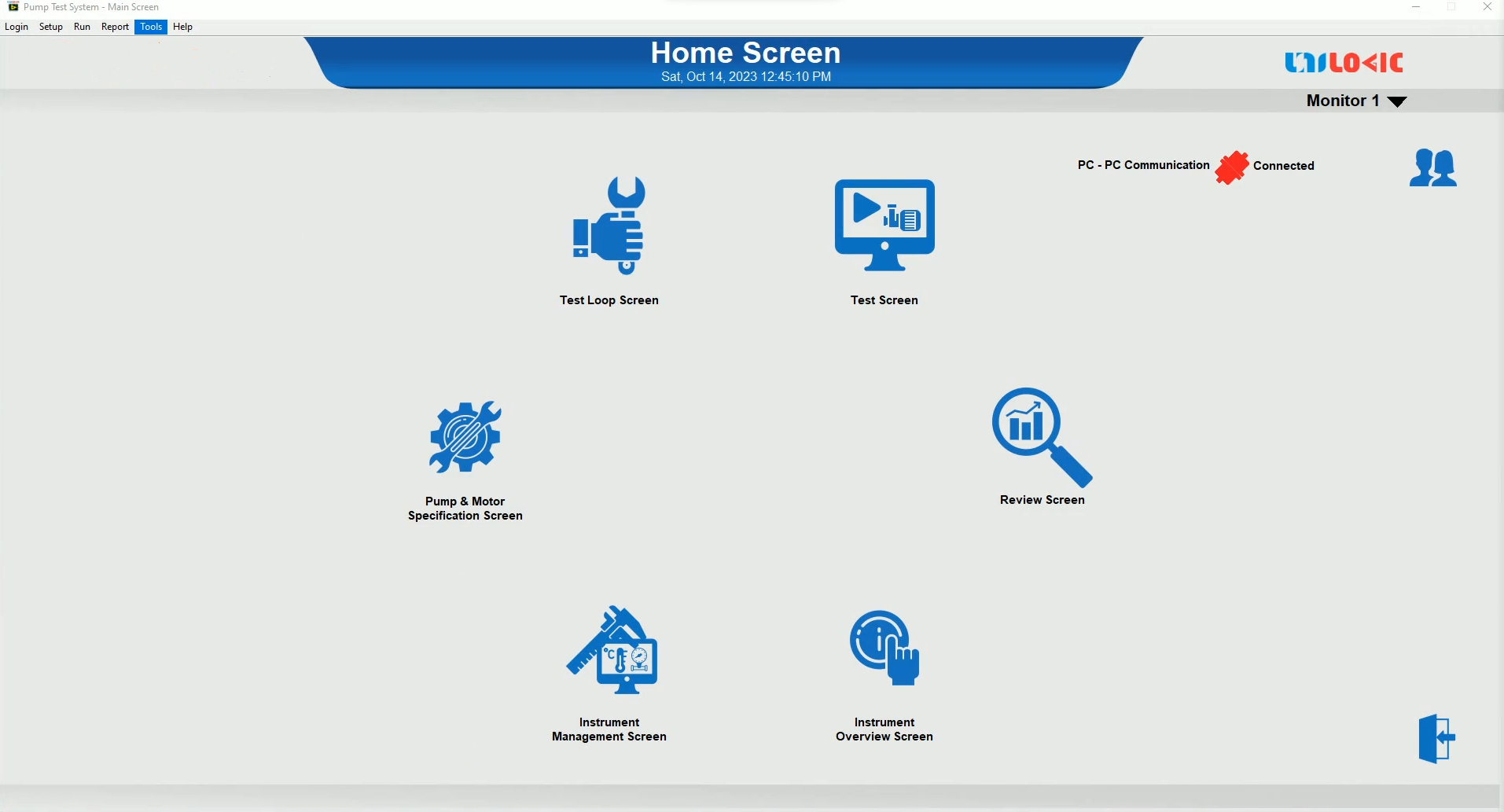

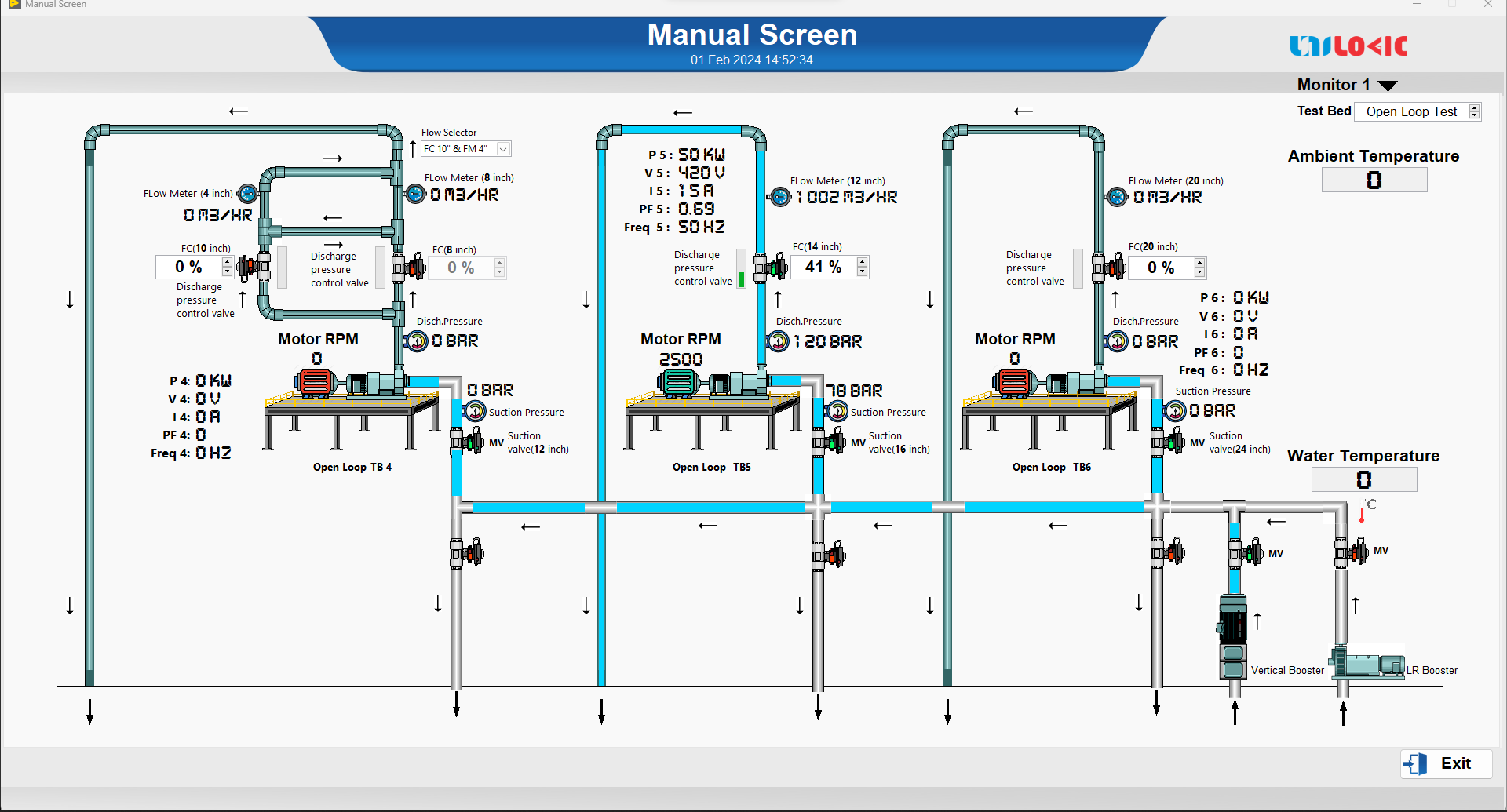

PC based highly precise automated test system to control and perform functional tests on a centrifugal pump. Centrifugal pumps are among the important equipment in any process plant. This system helps to analyze the performance and characteristics of the pumps at the assembly level and the end of line. Also allows to monitor and log the system parameters and calculating some other parameters like head, efficiency, etc.

The test system splits the software testing into units to provide precise results. The various tests conducted are as follows

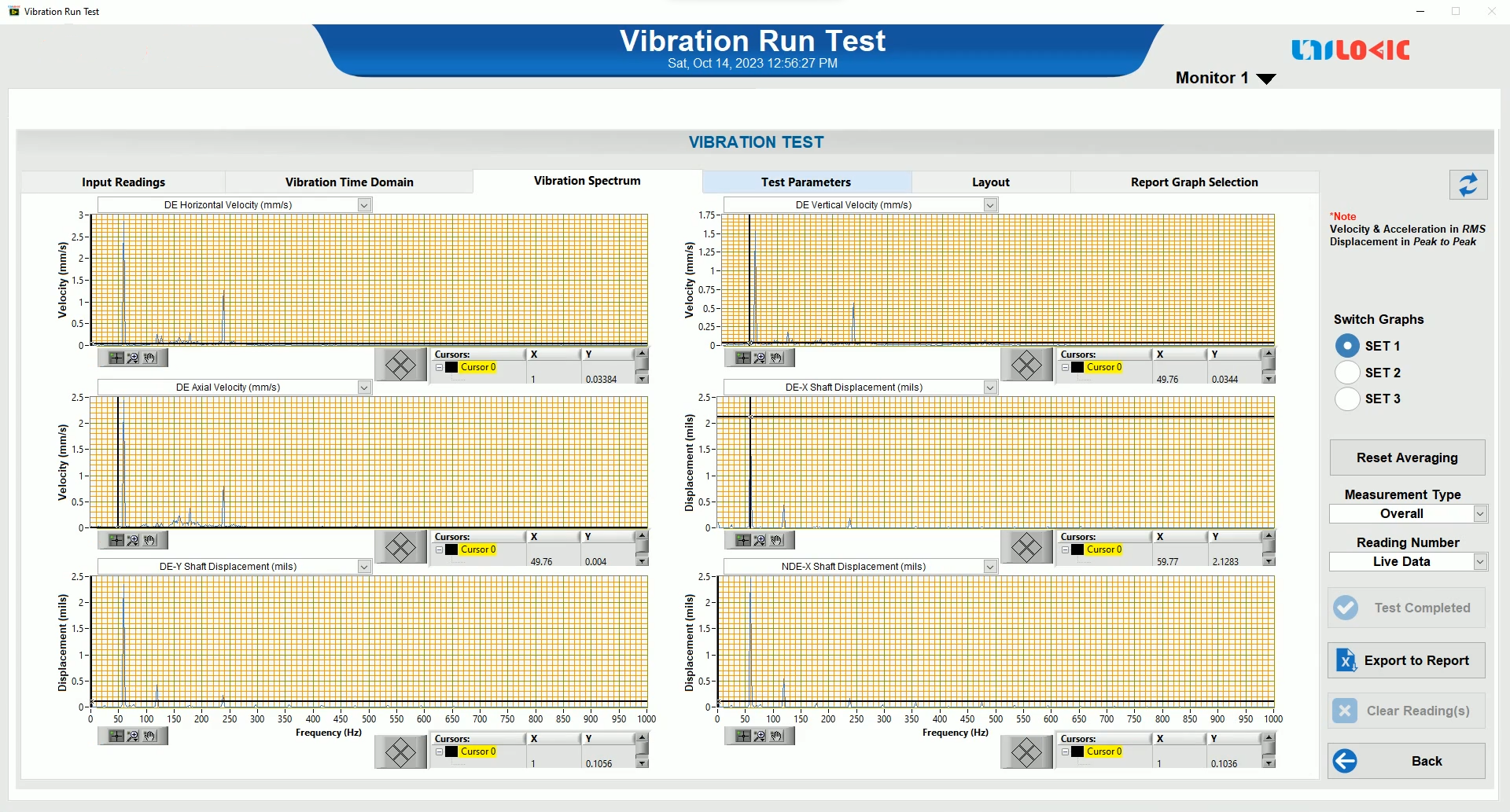

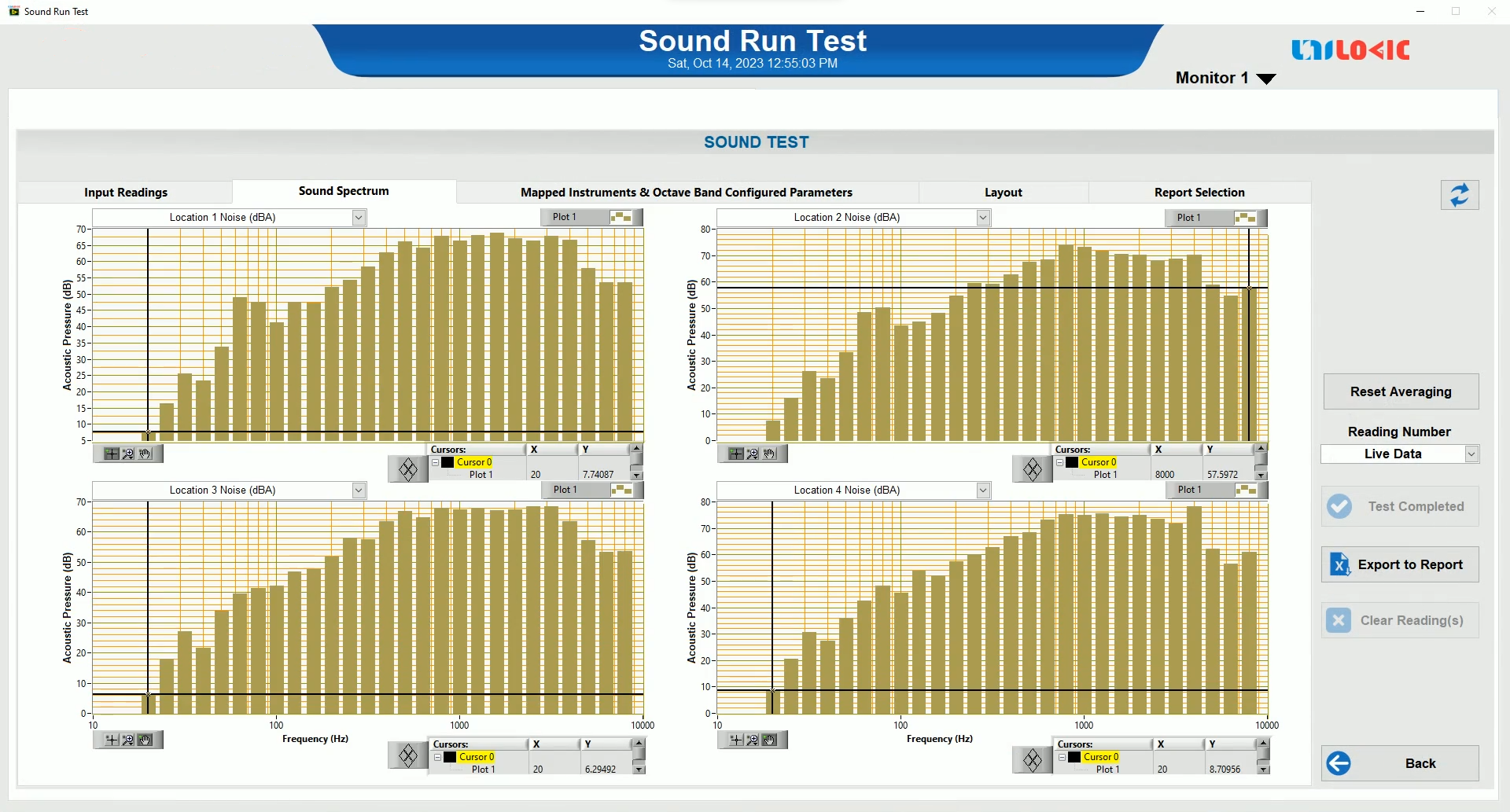

- Mechanical Run test

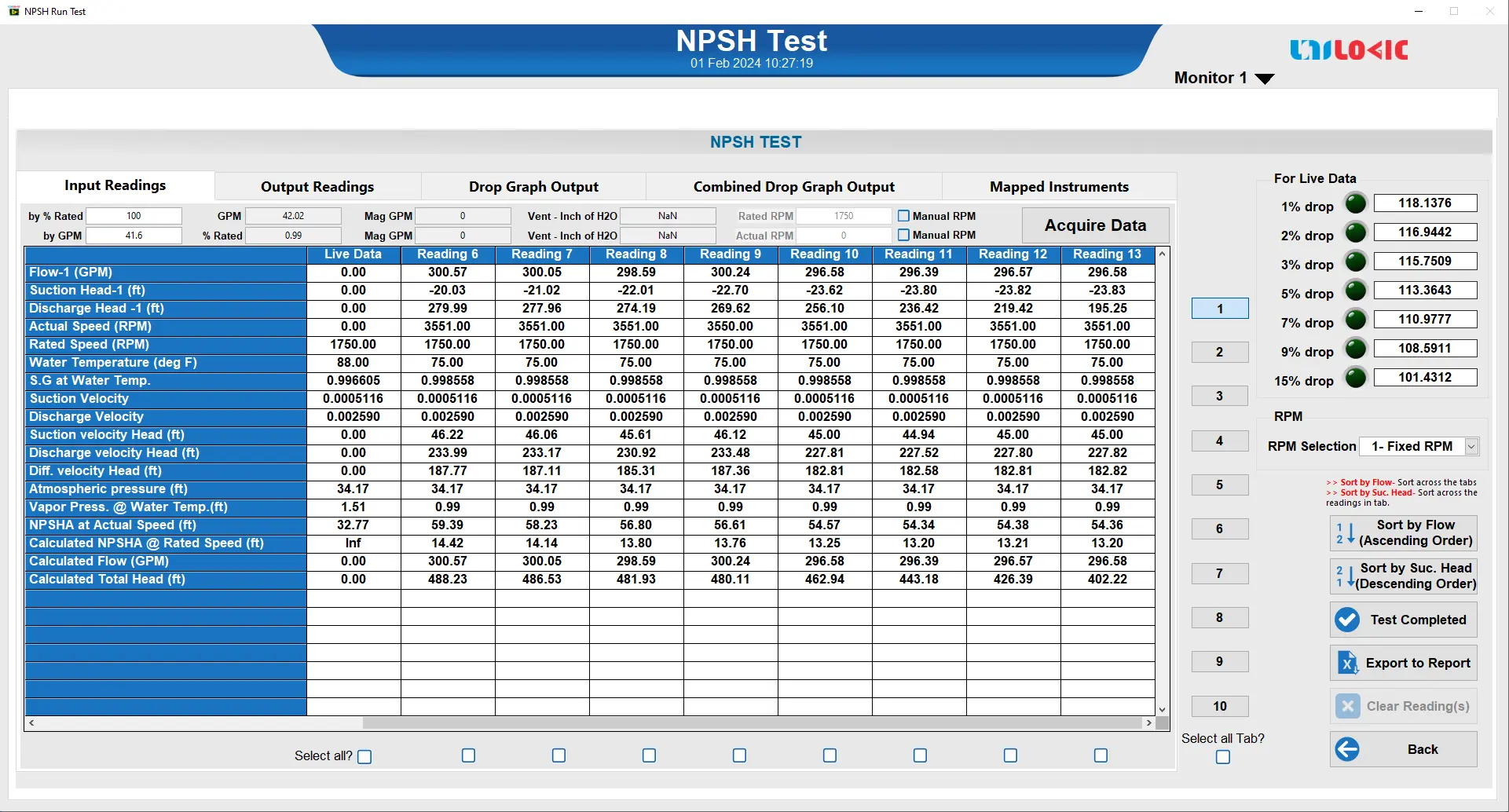

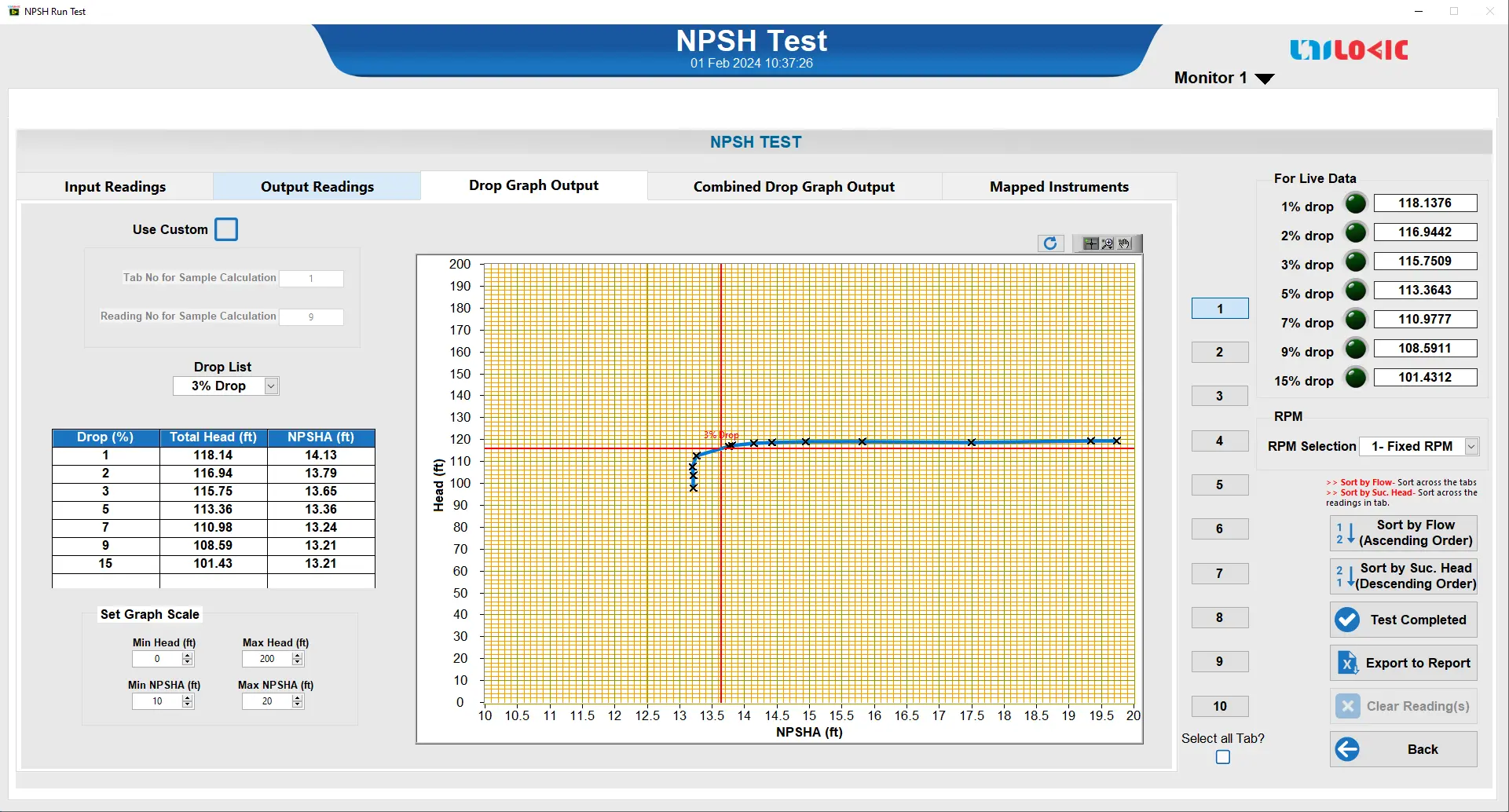

- NPSH – Net Positive Suction Head Test

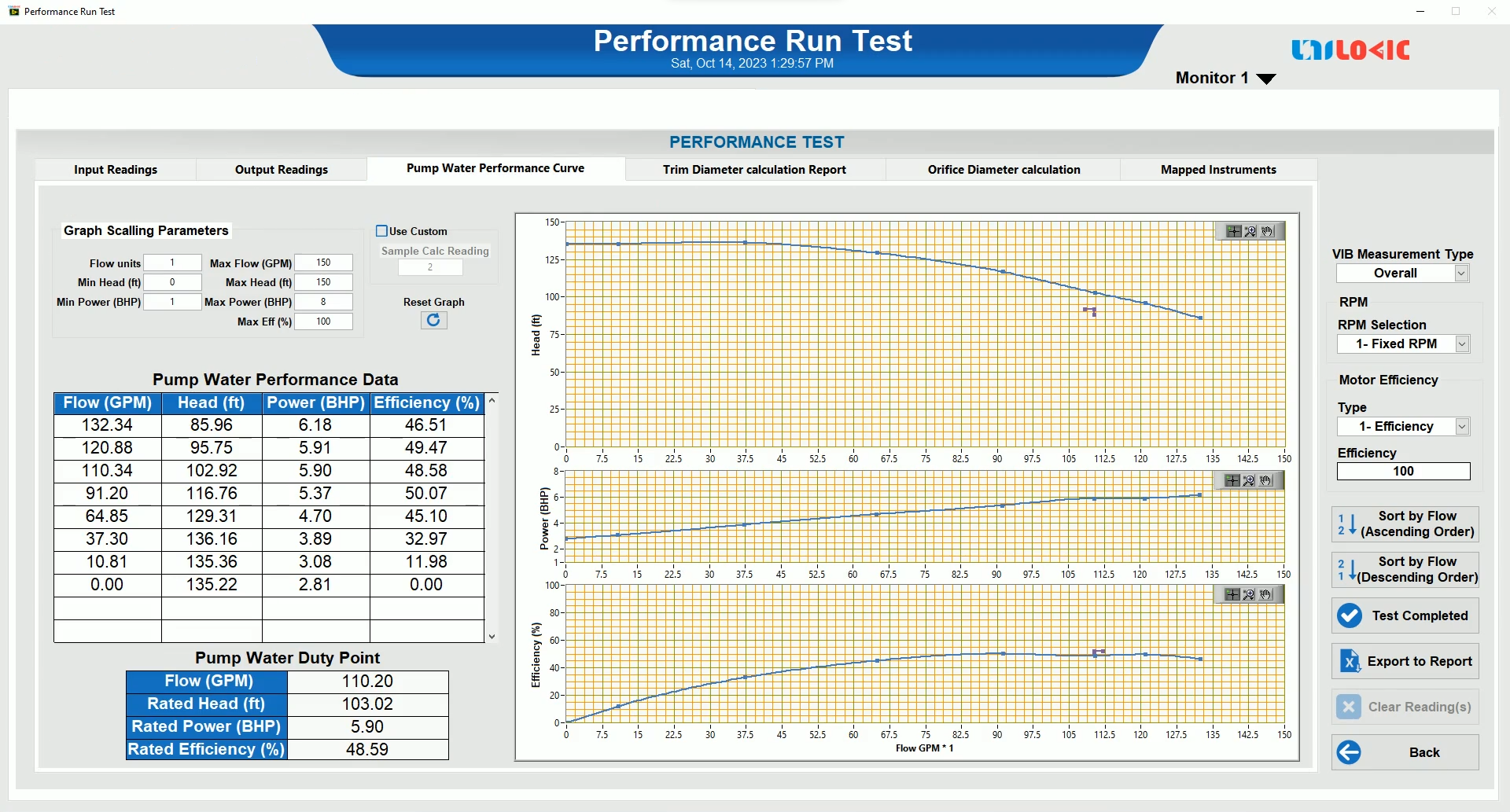

- Performance/Flow Rate test

- Pressure test

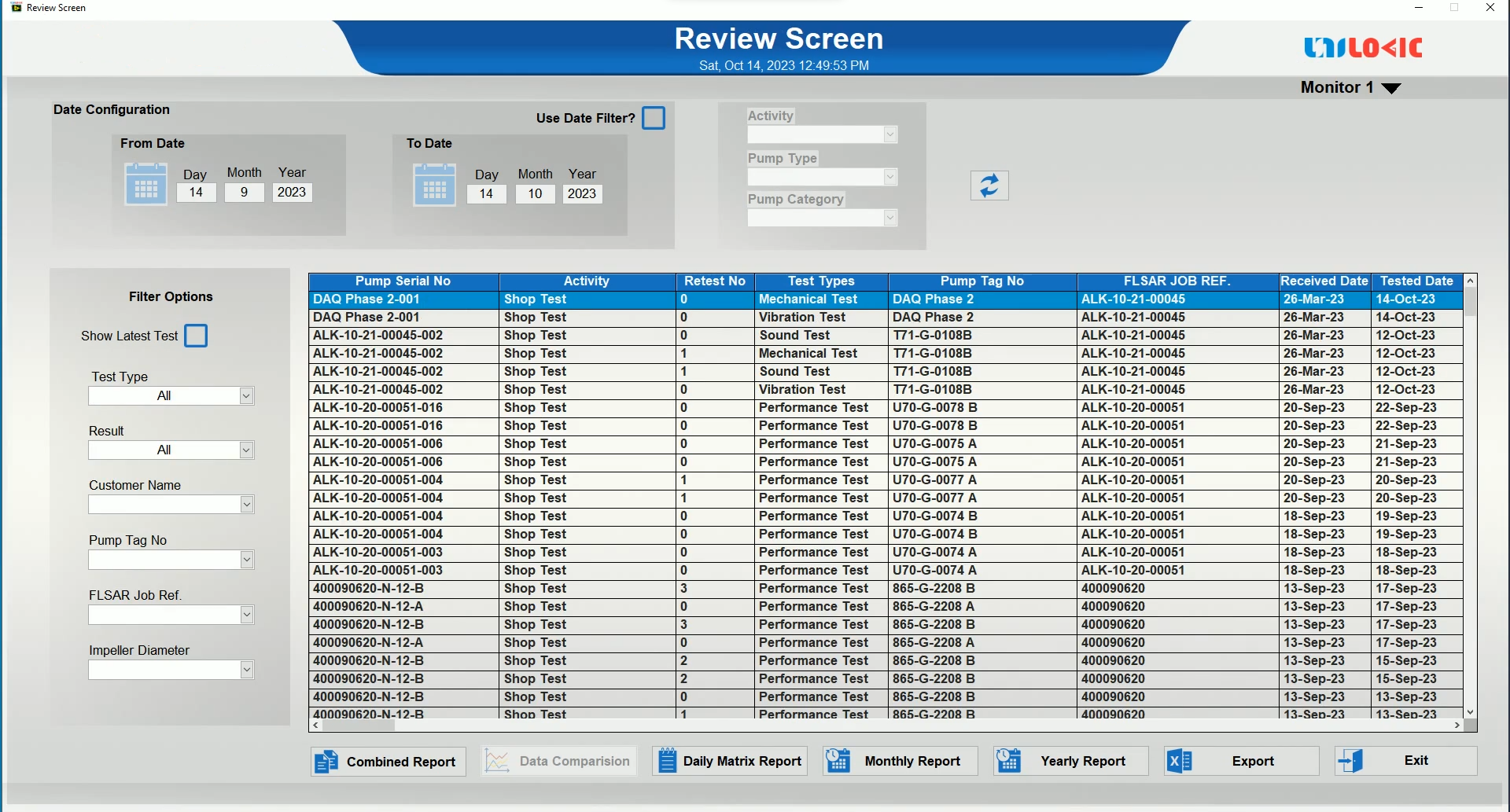

All the test Parameters are captured and verified by API or ISO standards which are automatically saved in database. Recorded test data can be retrieved in a graphical user interface in the form of graphs. It provides users with different filtering options. Also, exports report in PDF and Excel file formats.