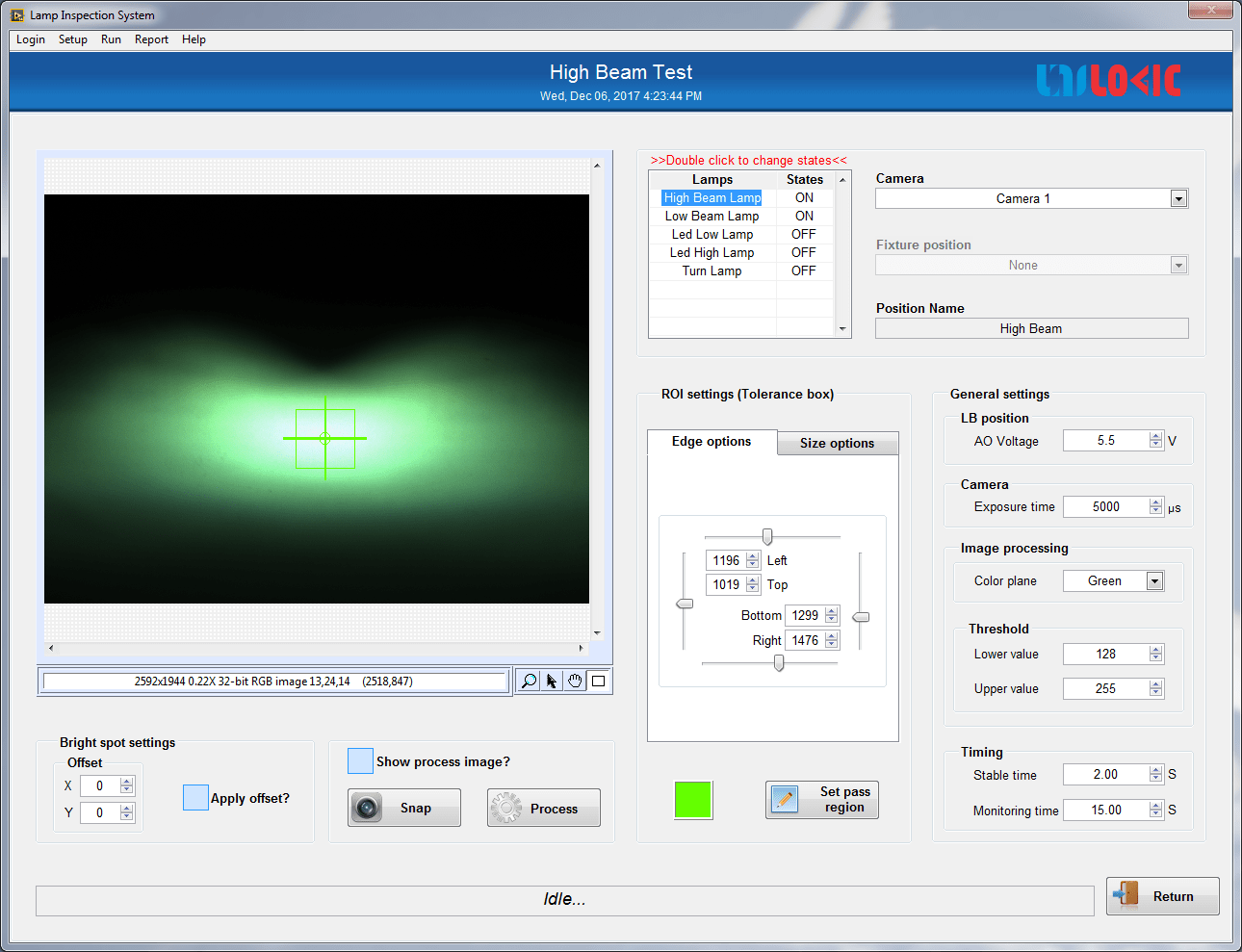

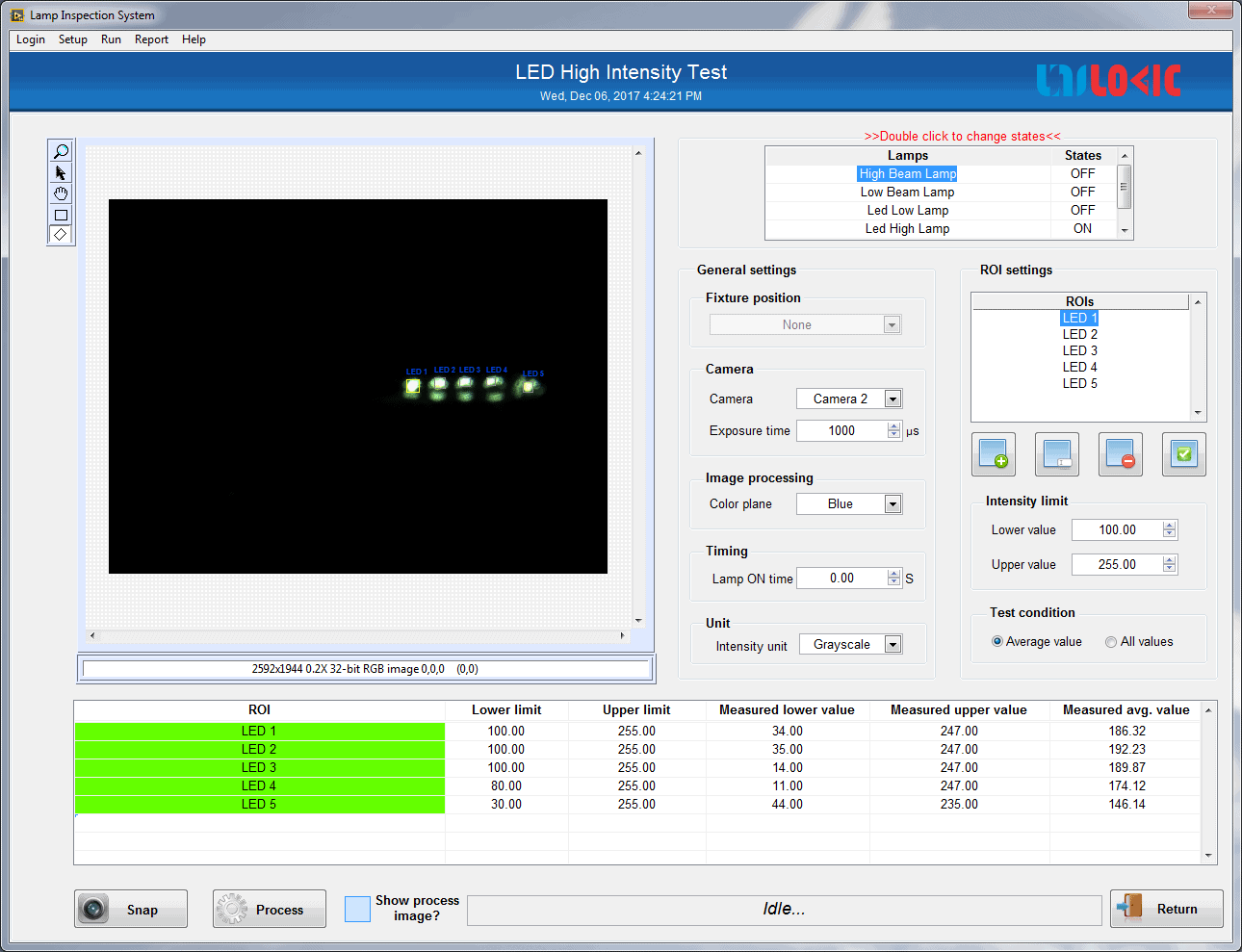

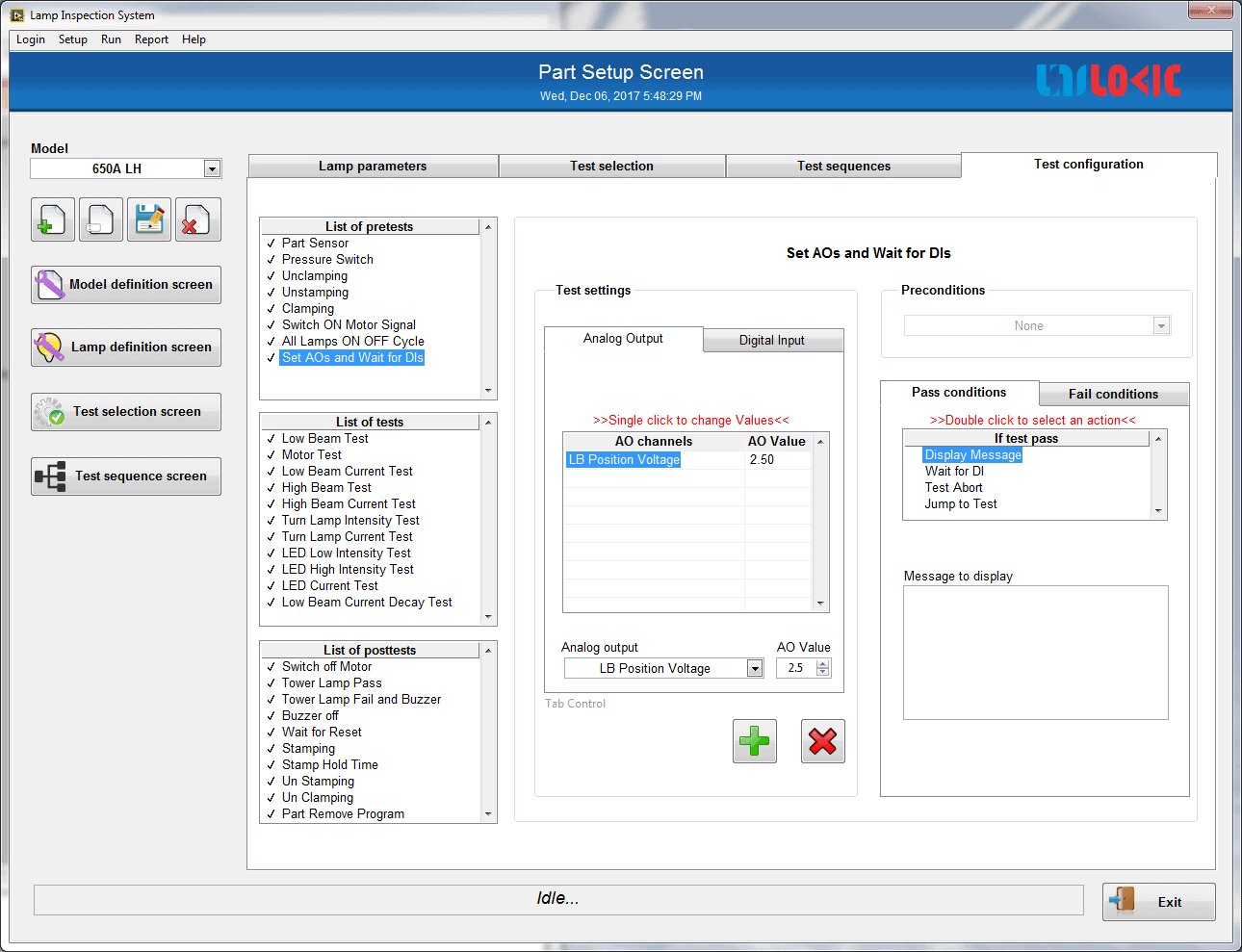

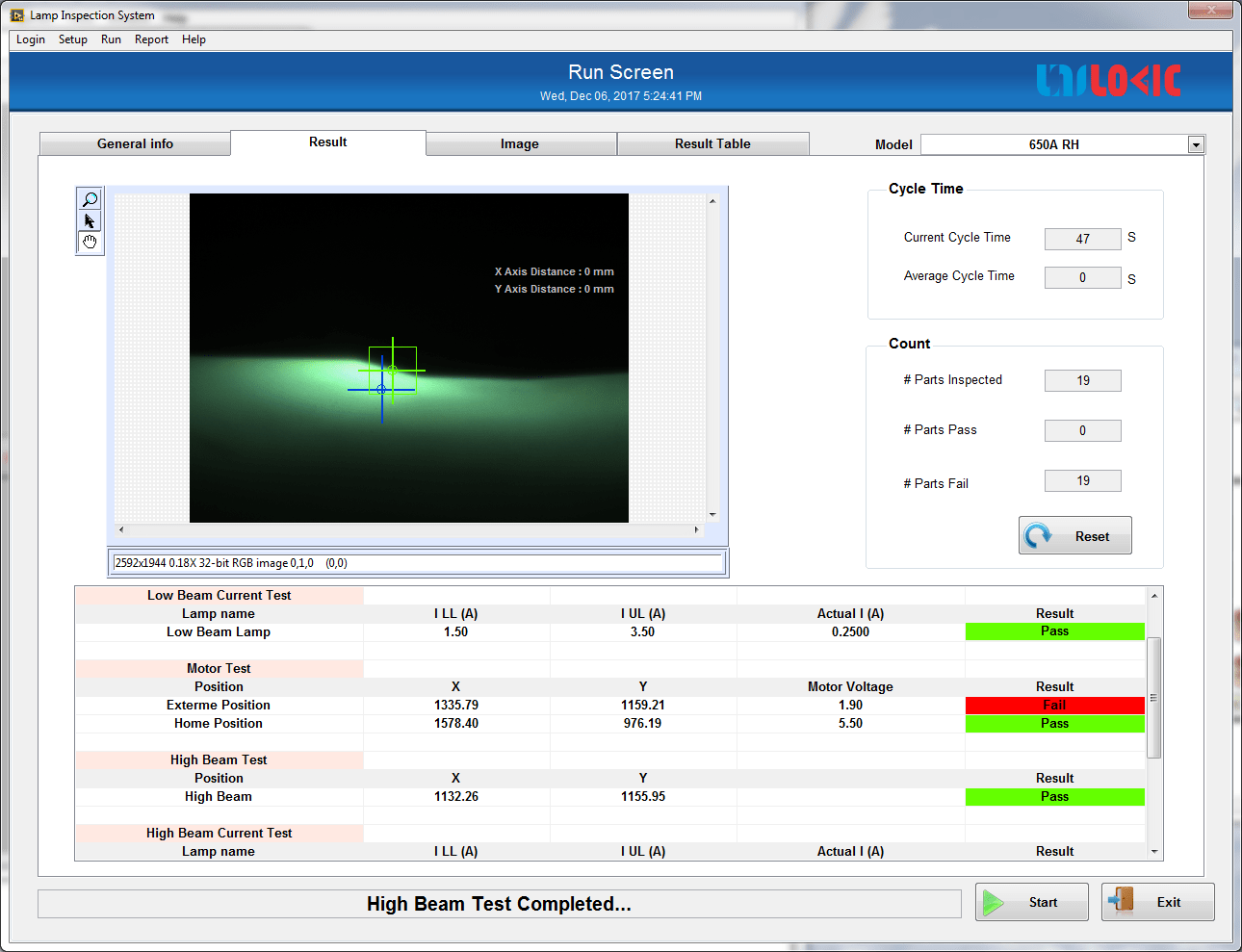

Low beam and High beam positions of the headlamp should be set and checked after getting assembled. The operator needs a visual guidance to set the correct beam position by adjusting the screws at the back of the headlamp unit. This vision system acquires the image of a light beam projected on a screen. By processing the image the system checks and guides the user to set the Low and High beam position. It also measures the Intensity level of the light projected and current consumption using a Data Acquisition System. Based on the cumulative results the system will accept or reject the lamp assembly. Passed models will be stamped and barcode printing is integrated with inspection details.

Benefits

- 100% online inspection

- User-configurable measurement system

- Immediate feedback to the operator to correct the lamp low and high beam positions

- Reduces the overall cost as the defects are identified before the Assembly