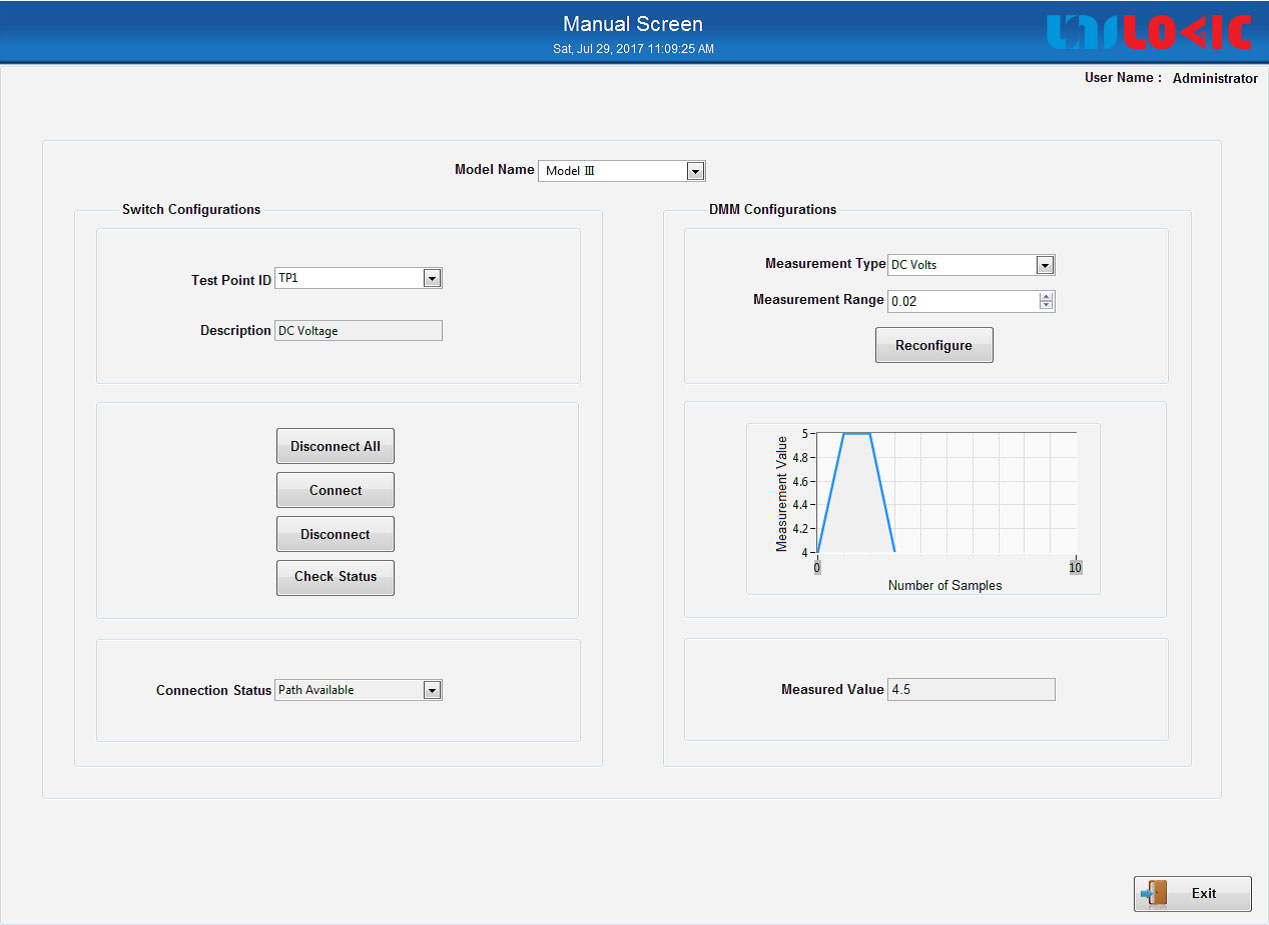

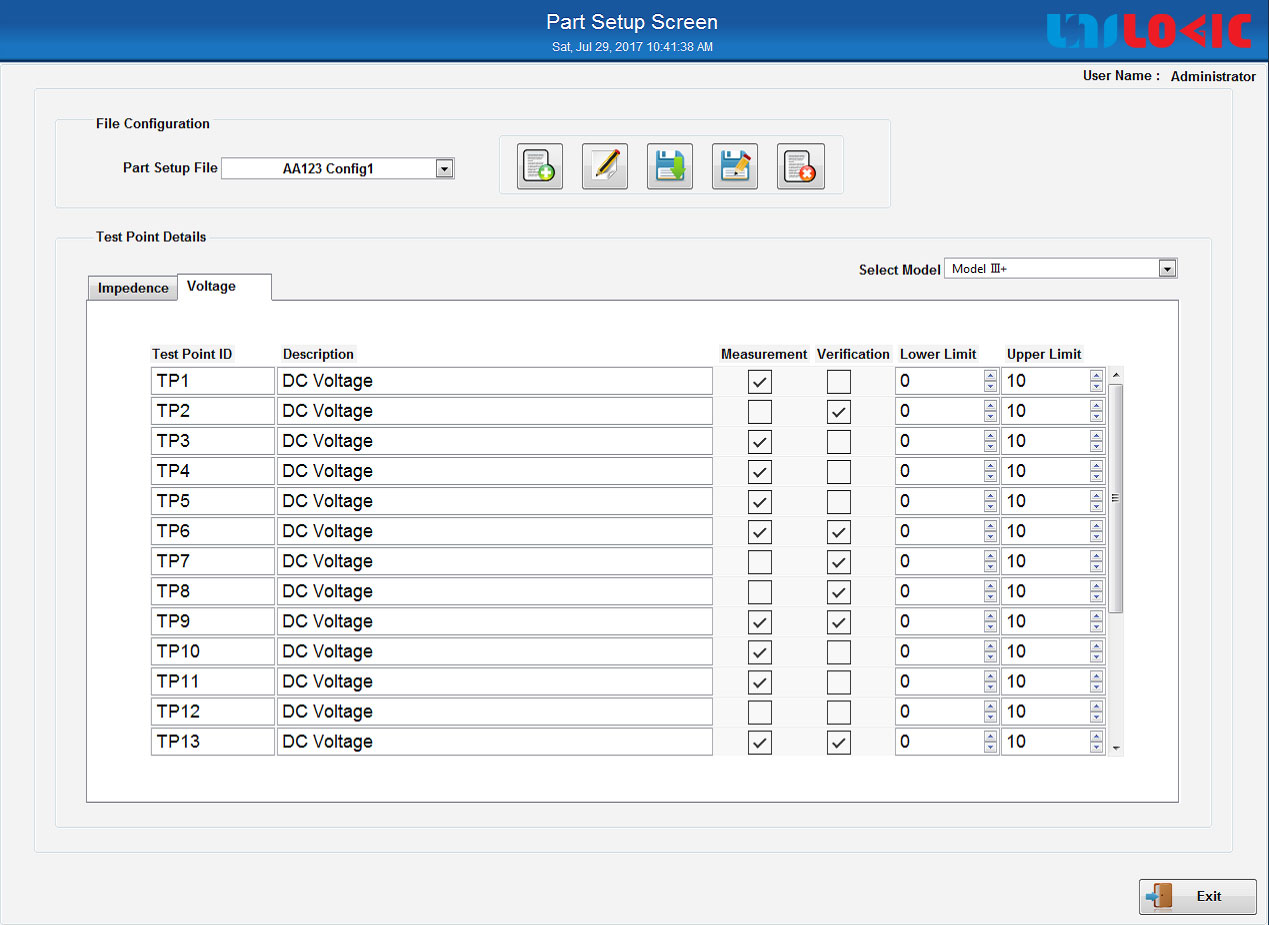

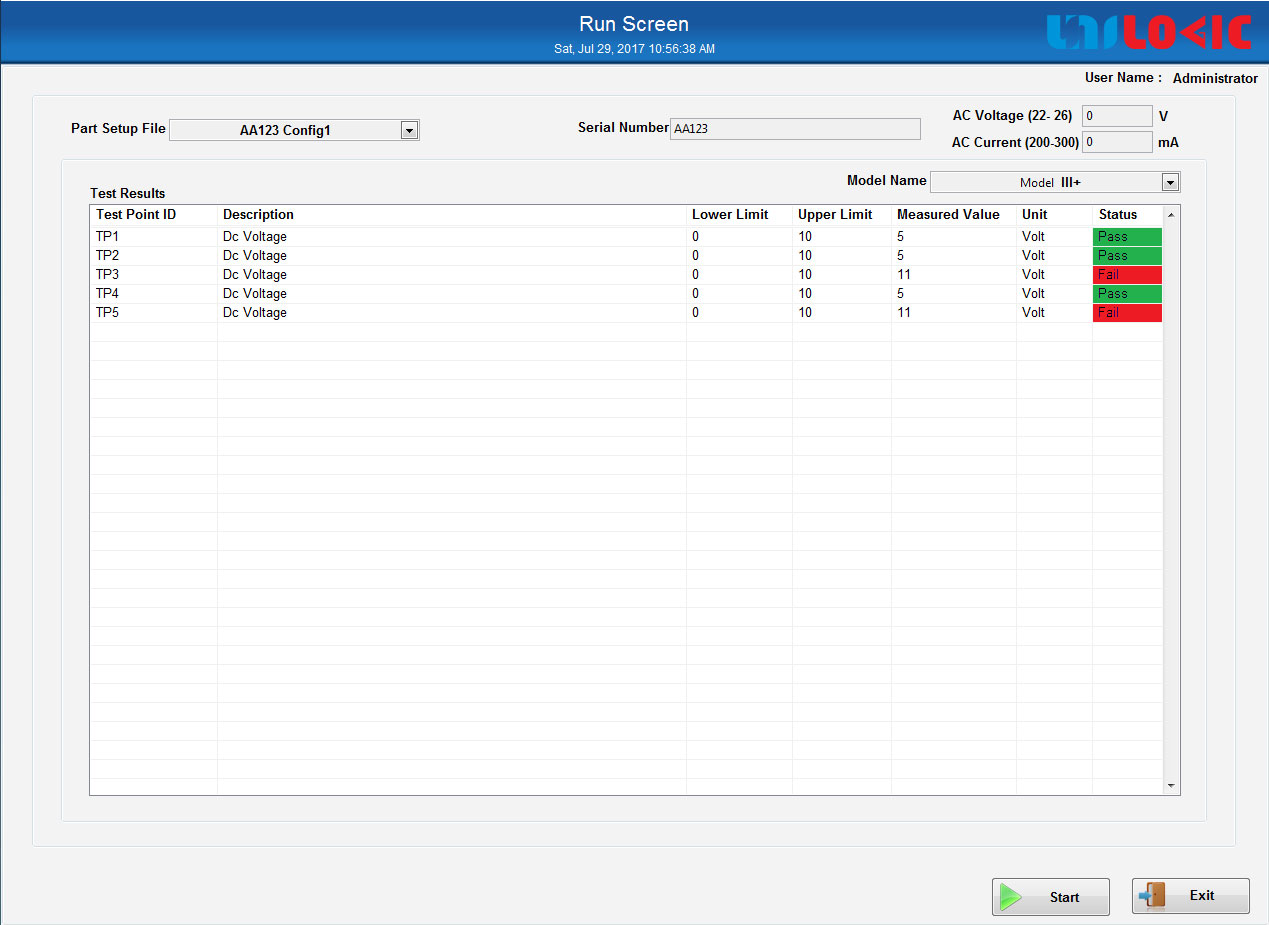

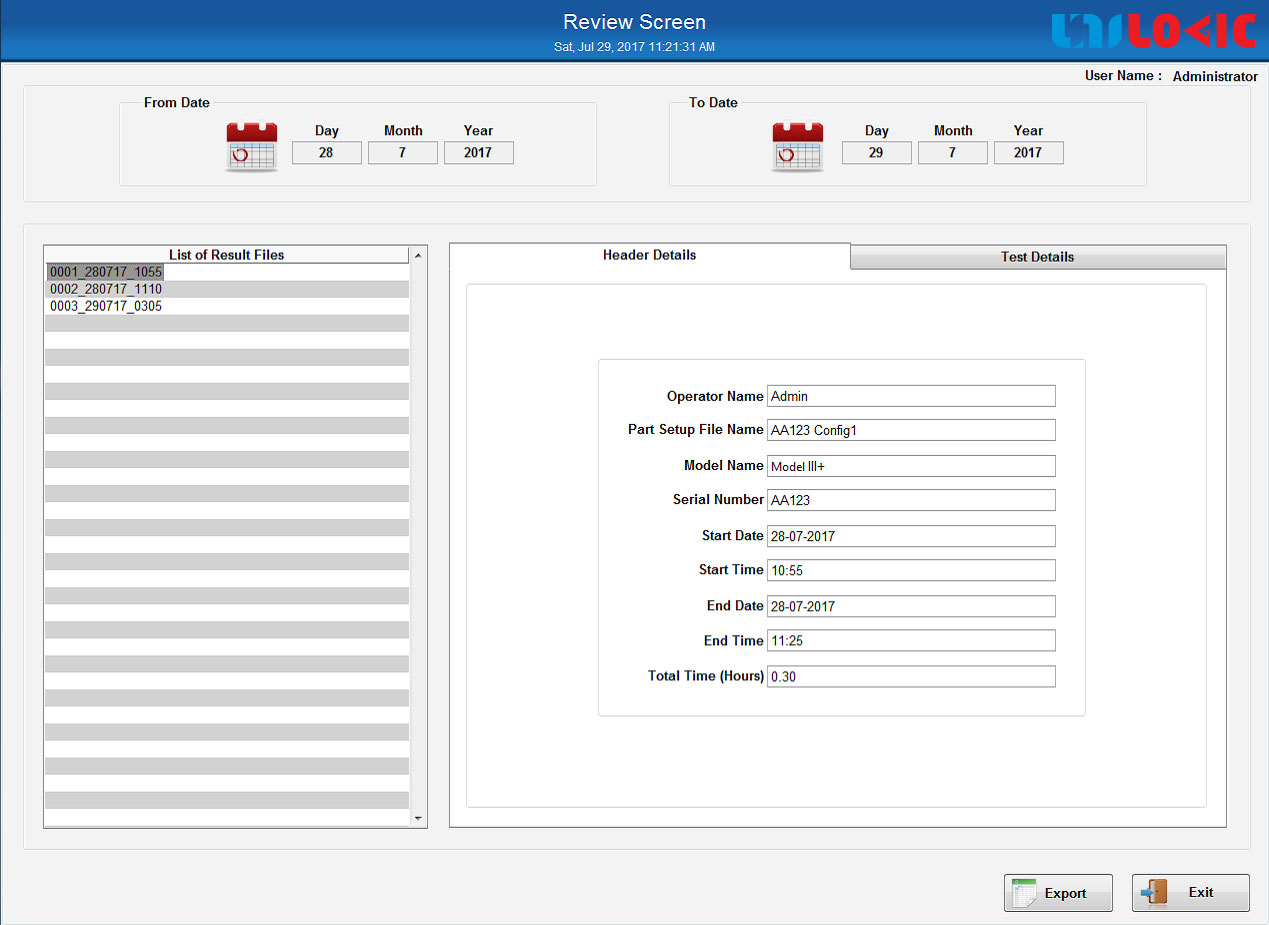

The Printed Circuit Board (PCB) Assembly which goes into any controller is tested by using bed of nail fixture (also called ICT test fixture). This test is used to check PCB manufacturing defects and bad components using the electrical properties (Open/Short circuit). Here, the faults of the test are located directly on the specific components, the device pins, and the network points, and the fault location is accurate, besides, it can greatly improve production efficiency and reduce maintenance costs. The program is under control of automated testing, so the operation is a simple, fast and rapid test.

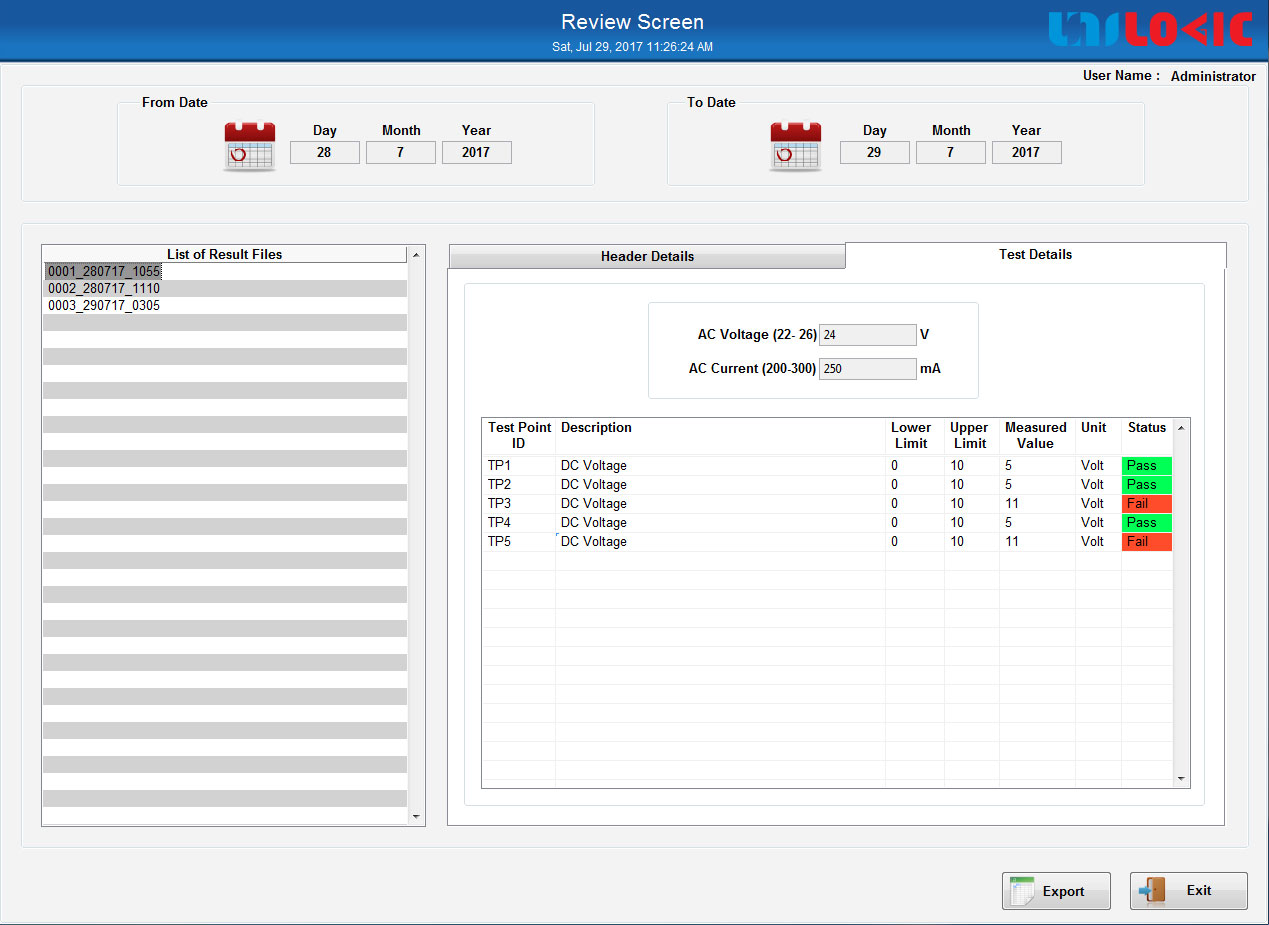

The test parameters that are measured across different combination of the bed of nail fixture

- AC Voltage

- AC Current

- DC Voltage

- DC Current

- Resistance

These parameters are compared against the user configurable specification. User has a provision to configure the test sequence and different bed of nail fixture. Test results will be saved into database and test report can be export in PDF file format. User can analyse the test results of different PCB Assembly boards in trend view screen of the test software.