Oxygen Sensor Test System is an automated test system to test the voltage and resistive type oxygen sensors at different lambda conditions and temperature in propane gas (fuel) burner; the Air-Fuel mixture will be controlled by solenoid valve assemblies. Standard lambda meter and reference sensor values can be compared with the sensor response. Light off test used to measure sensor response time over the cold start of the engine. The closed-loop test is used to measure the sensor response rate at the operating temperature. Open-loop test, Static Lambda Test and Wideband Test are the different test conducted on the sensor to measure Light-off_time, Closed-loop_frequency, Rich_voltage, Lean_voltage, Rich_to_vean_time, Lean_to_rich_time, and etc. Test results will be recorded in excel and pdf format.

Benefits

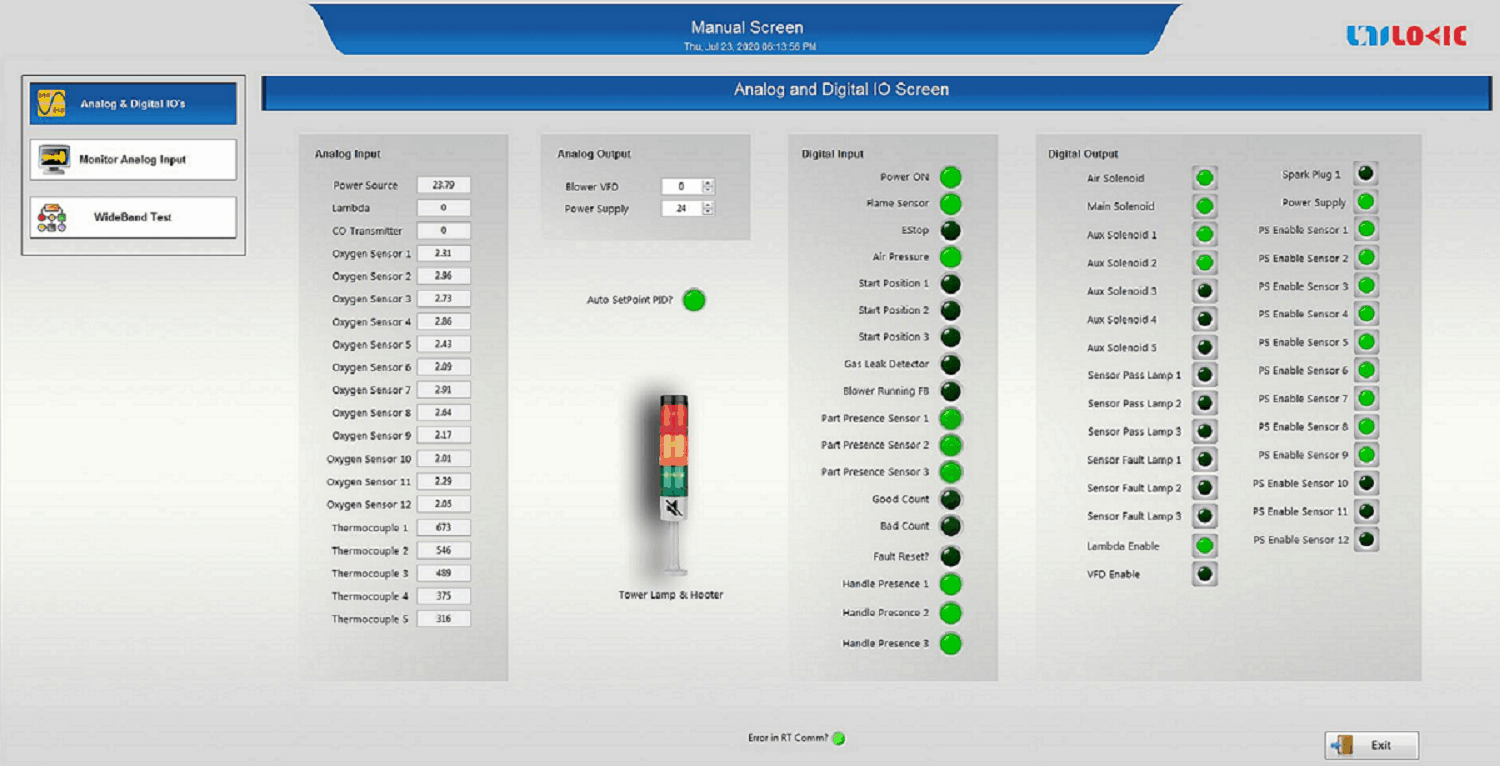

- Three Stage safety controllers with FPGA program, RT Program, and Electrical Relays.

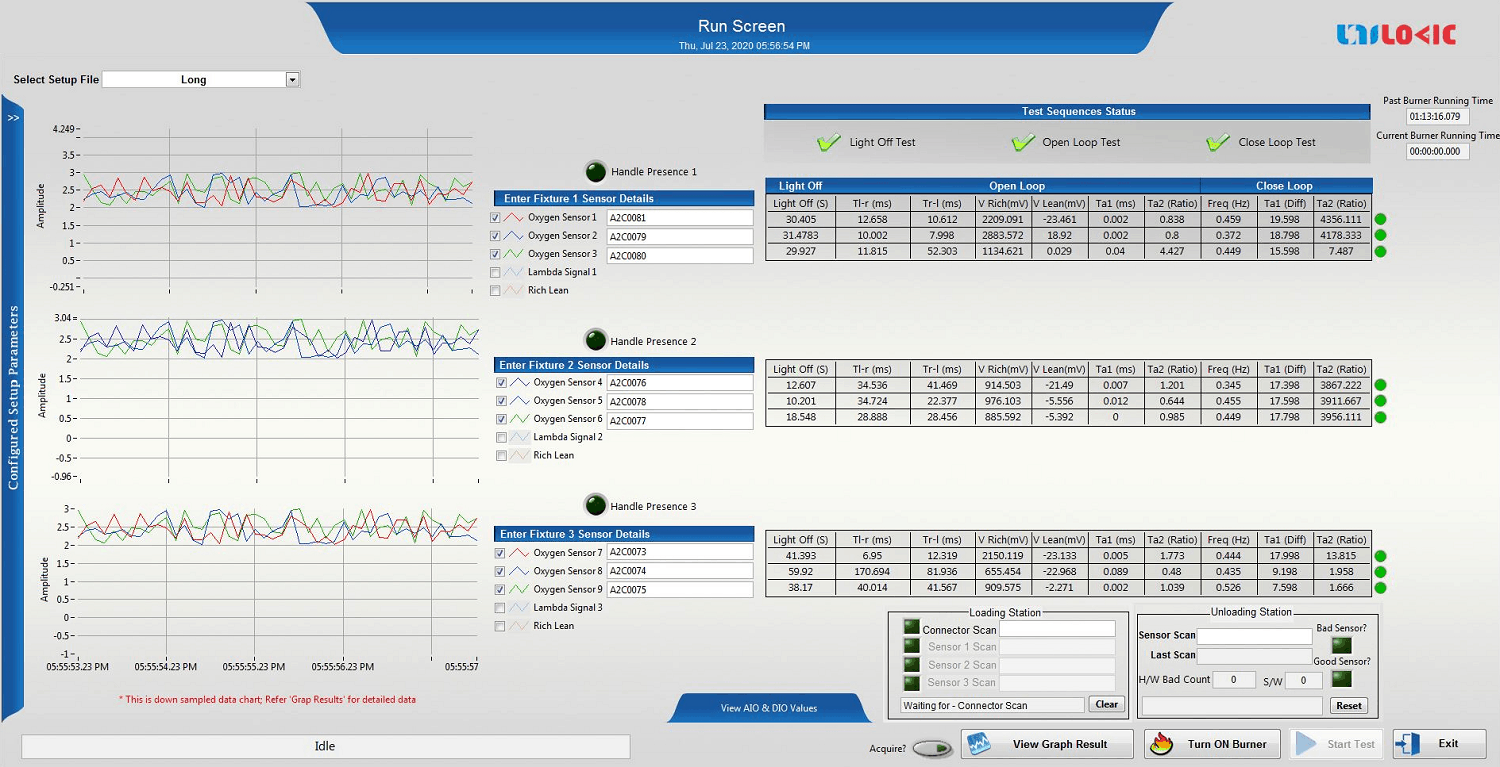

- Up to 9 Sensors can be tested (Batch Test)

- A single person can do all the tests.

- Parameters are logged automatically into Database.

- Waveforms can be compared with Standard lambda meter and a reference sensor.

- Automatic report generation.

- Less operating/testing time.

- Less power consumption (fuel and electricity)

Features

- Following are the tests are covered by the automated test software

• Narrow Band – Light Off Test

• Narrow Band – Open Loop Test

• Narrow Band – Closed Loop Test

• Narrow Band – Static Lambda Test

• Wide Band Test. - Following are the parameters will be measured, Light-off_time, Closed-loop_frequency, Rich_voltage, Lean_voltage, Rich_to_vean_time, Lean_to_rich_time and etc.

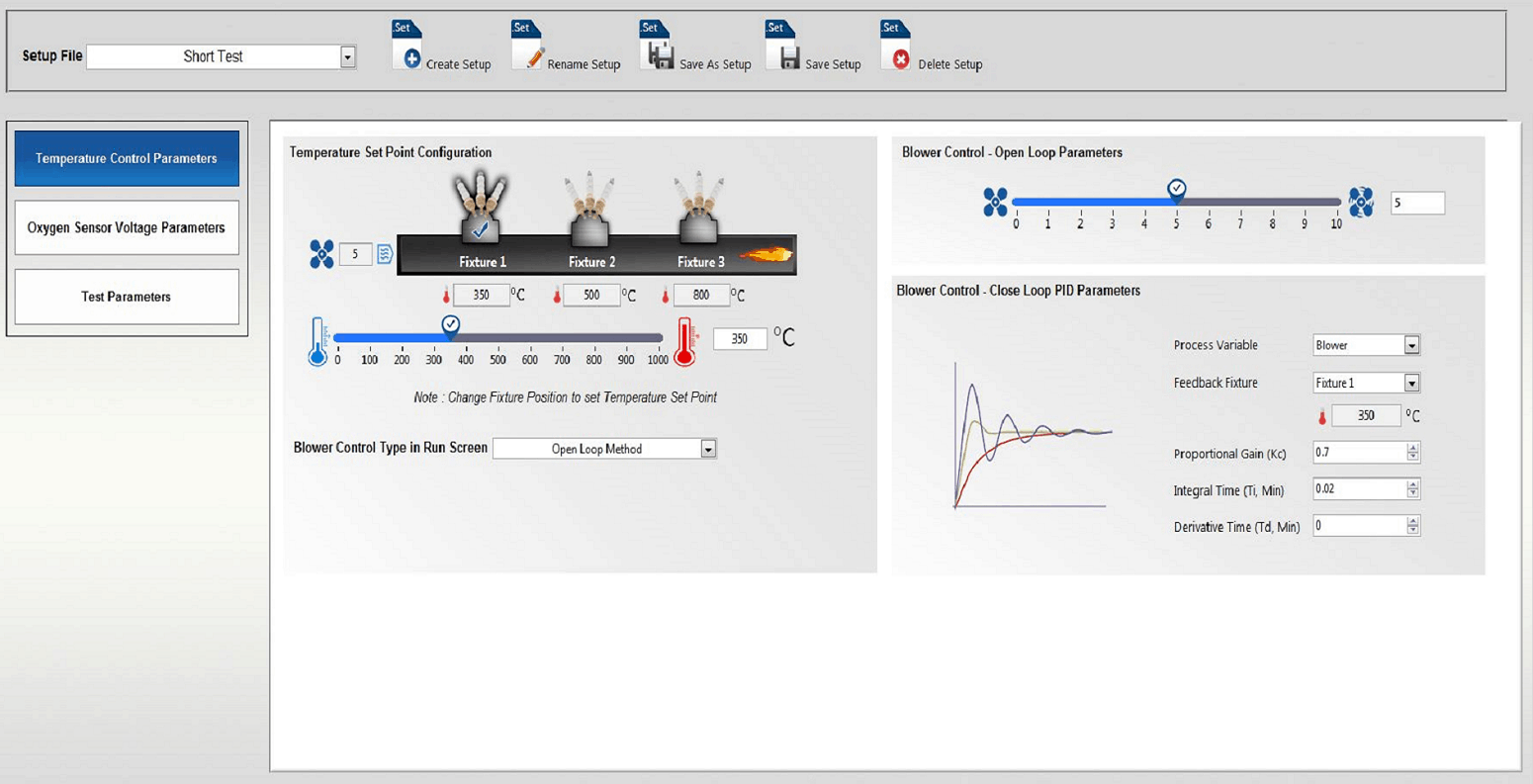

- Closed-loop temperature controller.

- Auto-generation of reports with excel and/or pdf formats.

- Provision to save and load different setup or configuration files.