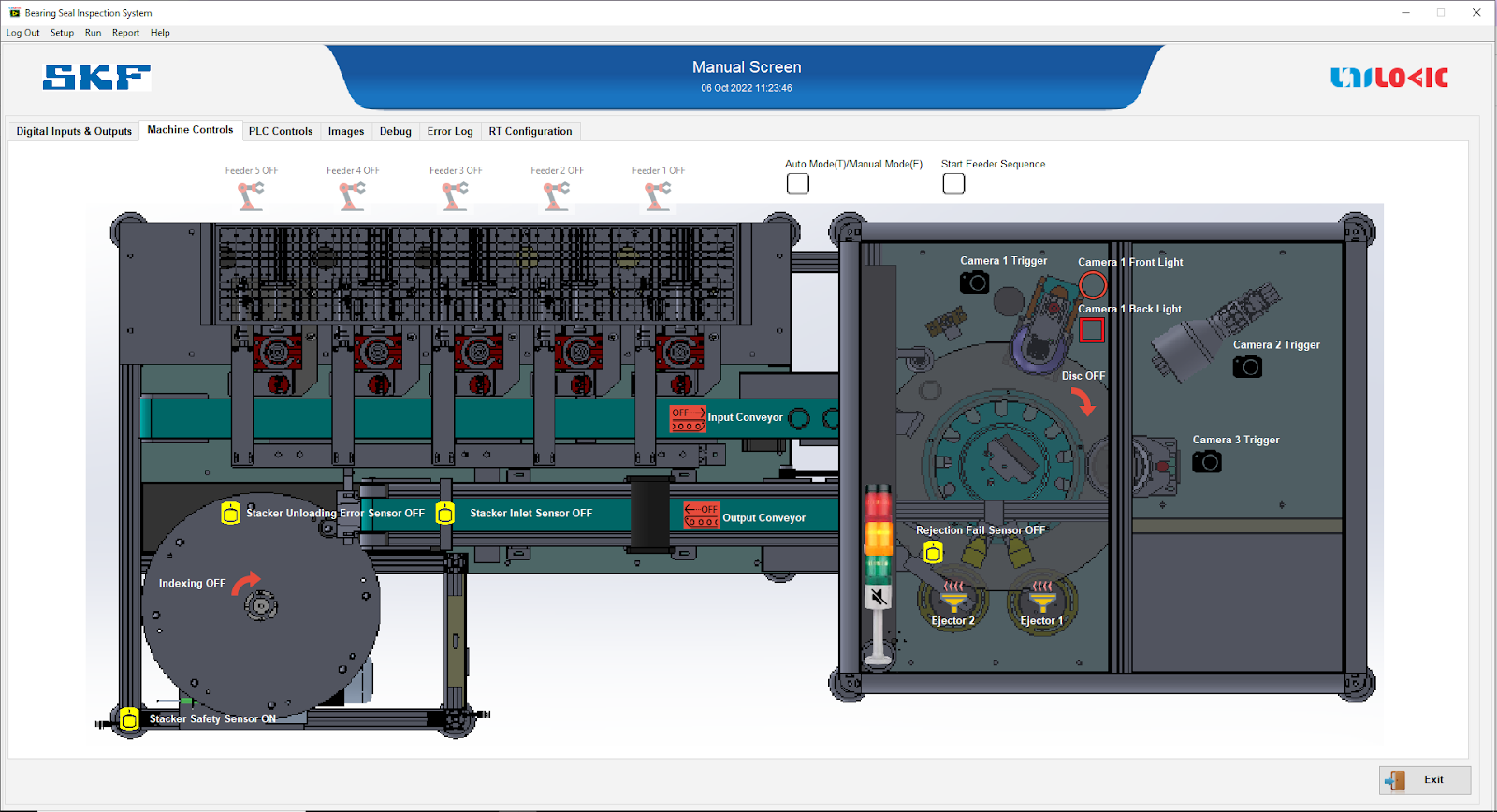

The Bearing Seal Inspection System (BSIS) automates the inspection process, requiring only one operator to load and collect segregated parts. This system has the capacity to inspect seals at a rate of 180 seals per minute, which is previously done by eight persons.

The operator loads the seals onto the pneumatic feeding system, which then feeds them to the inspection system in a sequential and aligned manner. The parts are transported by a conveyor and deposited onto a rotating disc. From there, the system captures images of the seals from various angles and positions for further analysis.

The collected images are processed using specialized algorithms for image analysis. These algorithms enable the software to distinguish between acceptable (OK) and defective (Not OK) parts. Any rejected parts are directed to a bin using a pneumatic ejector, while the accepted parts are stacked on the Indexing table.